Calcium silicate ceiling tiles production line

Product Description

2. good quality and service

3. competitive price

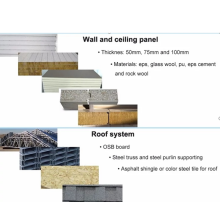

4. ISO CE approved 5. OEM,ODM Fiber Cement Board /Calcium Silicate Board Equipment Technology: Calcium silicate/ fiber cement board use inorganic mineral fiber or cellulosic fiber as reinforcement agent and siliceous material and calcareous material as main cementitious material. Process stages include: slurry preparation, board forming, stacking, pre-curing, module stripping, autoclaving and curing. To increase board quality, drying stage as well as sanding, edging and painting stages are added, which also increased additional value of board. Process technique contains molding –pressing process, flow-on process and hatcheck process. Main raw material: Reinforced fiber (pulp, wollastonite, glass fiber, mica, chrysotile and so on.), siliceous material (quartz powder, fly ash, diatomite and so on.), calcareous material (unslaked lime powder, cement) and additives. Standard of production: Calcium silicate board production based on Industry Standard JC/T564-2008 —“Fiber reinforced calcium silicate board”. Recomended application ceiling tiles partition wall interior decoration wall panel exterior wall cladding decoration etc. Application places office,commercial shopping mall,theater,exhibition room,building,house, free access floor; desktop board; sandwich panel; kitchen,washroom , etc Products property

Item | calcium silicate board |

Material | Cement, quartz sand, reinforced fiber |

Fire resistant | non-combustible Class A |

Density | 1.20-1.40g/cm3 |

Factory water rate | <10% |

Thermal conductivity | Mean 0.22W/MK |

Sound insulation | 45db |

Flexural strength | >16Mpa |

Moisture movement | <0.09% |

Dry shrinking rate | <0.09% |

Commodity | Fiber Cement Board |

Raw Material | Foam particles, cement, plant fiber, glass fiber cloth, non-woven fabrics, etc |

Density | ≤ 0.95 g/cm³ |

Size | 1220*2440mm or 1200*2400mm Customerization is available |

Thickness | 6~20mm |

Moisture Content | ≤ 8% |

Fire Rating Test | Class A1 incombustible material |

Moisture Movement | ≤0.12% |

Bending Strength | ≥ 8.5 Mpa |

Maximum Service Temperature | 1200 °C |

Water Permeability | No water vapor after 24 hours' test |

Refractoriness | 4H |

Coefficient of Thermal Conductivity | ≤0.2 W/MK |

Color | Grey |

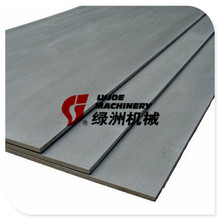

Pictures Equipment pictures

Finished products and application

Finished products and application  Packaging & Shipping Packing details:standard package for export or according to requirement Delivery details:within 3 months after the receipt of deposit Shipment:by sea Our Services 1) The machine guarantee1 year except the easy worn parts such as bearings, electric buttons. 2) Machine installation and commissioning: Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to guarantee the machine good running, each year we will send engineer to check and develop the technology. 5) If the buyer can not run the machine well then we will send the engineers to help the buyer to run the machine, and we can cooperate for long terms. Company Information We specilize in manufacturing machinery of building material. For examply gypsum board production line,Calcium silicate board production line,fiber silicate board production line, polystyrene particles fireproof insulation production line etc. Welcom to browse our website for more detailed information about our company and products. Pls contact us directly if you have any questions or need. Please feel free to contact me if you have any question. Tina Niu Whatapp ID: 86 159 324 888 03 Email address: lvjoe1 at china-machines.com.CN(no blank) Contact us if you need more details on calcium silicate board production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Calcium silicate ceiling tiles production line、Fiber cement board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Packaging & Shipping Packing details:standard package for export or according to requirement Delivery details:within 3 months after the receipt of deposit Shipment:by sea Our Services 1) The machine guarantee1 year except the easy worn parts such as bearings, electric buttons. 2) Machine installation and commissioning: Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to guarantee the machine good running, each year we will send engineer to check and develop the technology. 5) If the buyer can not run the machine well then we will send the engineers to help the buyer to run the machine, and we can cooperate for long terms. Company Information We specilize in manufacturing machinery of building material. For examply gypsum board production line,Calcium silicate board production line,fiber silicate board production line, polystyrene particles fireproof insulation production line etc. Welcom to browse our website for more detailed information about our company and products. Pls contact us directly if you have any questions or need. Please feel free to contact me if you have any question. Tina Niu Whatapp ID: 86 159 324 888 03 Email address: lvjoe1 at china-machines.com.CN(no blank) Contact us if you need more details on calcium silicate board production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Calcium silicate ceiling tiles production line、Fiber cement board production line. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : fiber cement board production line

Premium Related Products