1million square meter to 10 million square meter fiber cement sheet making machine

Product Description

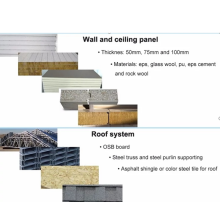

Raw material: Cement Fly Ash ,Lime,paper Pile,Sand can be used the raw material,no need used all, the percent for per kind raw material according the customer requirement. The board specification:

Raw material: Cement Fly Ash ,Lime,paper Pile,Sand can be used the raw material,no need used all, the percent for per kind raw material according the customer requirement. The board specification: Iterm | Unit |

|

density | g/cm3 | 0.8to 1.5 |

Heating modulus | Mpa | >9 |

Impacting –proof strength | W/M.K | <0.29 |

Screw puling out power | Kj/MM2 | >2.0 |

Drying shrinking rate | N/mm | <0.2 |

|

|

board making system: Reserve bucket constantly pulp slurry into the Head box to wandering, wandering head box the one hand, stirring to prevent precipitation, on the other hand through the slurry obtained Pulp board evenly slip to Felt,Flat function vacuum in vacuum boxes Felt on the adsorptiorl layer of water expected to gradua11y reduce demand through the molding material formed cones set Up to billet thickness,mechanical or pneumatic cylinder forming a knife, was sent to the slab under the procedure.

board making system: Reserve bucket constantly pulp slurry into the Head box to wandering, wandering head box the one hand, stirring to prevent precipitation, on the other hand through the slurry obtained Pulp board evenly slip to Felt,Flat function vacuum in vacuum boxes Felt on the adsorptiorl layer of water expected to gradua11y reduce demand through the molding material formed cones set Up to billet thickness,mechanical or pneumatic cylinder forming a knife, was sent to the slab under the procedure.

This equipment is specially producing building flat and ripple board and is widely applied for billet sucking and stacking of shaped calcium silicate board. board's sucking of set adhesive tape, the device willf1inish following process: sucking itself, transverse cutting, moulding and tacking. lt is method with hydraulic pressure lift table and billet holding machine.

This equipment is specially producing building flat and ripple board and is widely applied for billet sucking and stacking of shaped calcium silicate board. board's sucking of set adhesive tape, the device willf1inish following process: sucking itself, transverse cutting, moulding and tacking. lt is method with hydraulic pressure lift table and billet holding machine.The equipment is made up of mainframe stand,wind machine,billet sucking lift system, main body,tuming guide of main body,transverse cutting and hydraulic pressure system, etc.

Contact us if you need more details on fiber cement sheet making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about professional fiber cement board machine manufacturer、lightweight waterproof fiber cement board machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on fiber cement sheet making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about professional fiber cement board machine manufacturer、lightweight waterproof fiber cement board machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : fiber cement board production line

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery