4 Column Hydraulic Press For Head Cover 100T

Basic Info

Model No.: Yz32

Product Description

4 Column hydraulic press Machine For Deep Drawing

The head hydraulic press can also be used for correction, press fitting, packing, pressing and pressing, etc. It can also be used for the pressing process of shaft parts, profile calibration, crimping, press-fitting process and bending, arguing, shaping and stamping of sheet metal parts. , sleeve, stretch, Plastic material pressing process, such as stamping, bending, flanging and thin stretching, etc., can also be engaged in the correction, press-fit, plastic products and powder products press forming operations, due to its wide range of applications Known as the universal hydraulic press.

The head and return stroke of the head hydraulic press can be high speed, and the speed of the work stroke can be adjusted according to the need. When the work stroke is actively switched to the return stroke, it can be controlled by the stroke direction or the hydraulic machine effect force, and can also be given a predetermined effect. Force applied a switch after the booking time. The operation mode includes active stroke, single stroke and inching. The hydraulic machine can be equipped with active feeding of the blank, active transfer of the workpiece between the stations and active unloading of the forging. The number of ejector in the working table can be regarded as Single or multiple stations are equipped. The filling valve is used on large and medium-sized hydraulic machines. These equipment cylinders are large, and the oil is supplied by the oil pump. The downward speed is too slow, which affects the production power. An oil tank is placed on the top of the press, and the upper tank and the upper chamber of the cylinder are placed. When the piston is lowered, the filling valve is opened, and the oil in the upper tank is directly filled into the upper chamber of the cylinder. When pressurized, the filling valve is closed and pressurized by the oil pump. When the piston rises, the filling valve opens and the oil in the upper chamber of the cylinder returns to the upper tank.

The head cover hydraulic press filling valve can also be set with pre-opening pressure and has a firm sealing function. It is widely used in hydraulic press forging machinery, which can make the press cylinders have the effect of rapid oil filling and oil discharge, at high pressure and large flow. It can play the unloading effect and avoid the unloading impact. The liquid filling is usually used as the suction and discharge valve between the hydraulic and the fuel tank. When the large press is rushing, the cylinder should make up a lot of oil, and the idea is to suck the oil into the fuel tank; When the pressure is applied, the oil should be prevented from returning from the oil tank to the oil tank. In the reverse direction, the oil can be drained from the oil cylinder to the oil tank. Exquisitely processed, fine height, no leakage, excellent pressure retention function, and a slow-moving valve core, it can be used to reduce the sound and vibration. Widely used in high speed presses, presses, injection molding machines and other machines.

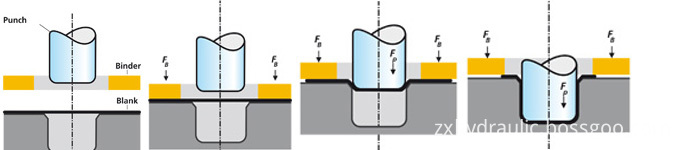

When drawing complex body parts in practice, it usually involves a combination of stretching and deep drawing. The metal sheet must be stretched as much as possible without reaching the limits of the material (eg cracks, wrinkles).

The deep drawing process is a forming process that takes place under a combination of stretching and compression conditions. Forming the flat metal blank into a hollow body that is open on one side or forming the hollow body into a hollow body having a smaller cross section,

Parameter

| Model | unit | Yz32-40 | Yz32-63 | Yz32-100 | Yz32-160 | Yz32-200 | Yz32-250 | Yz32-315 | Yz32-500 | Yz32-630 | Yz32-800 | Yz32-1000 | Yz32-1600 | Yz32-2000 | |

| Nominal Force | KN | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 | 6300 | 8000 | 10000 | 16000 | 20000 | |

| Ejection force | KN | 63 | 100 | 250 | 250 | 400 | 400 | 630 | 1000 | 1000 | 1250 | 1250 | 1600 | 2000 | |

| Max working pressure of liquid | Mpa | 26 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max. open height | mm | 400 | 600 | 800 | 900 | 1000 | 1000 | 1250 | 1400 | 1500 | 1500 | 1500 | 1600 | 1800 | |

| Slider stroke | mm | 300 | 400 | 600 | 700 | 700 | 700 | 800 | 900 | 900 | 900 | 900 | 900 | 1000 | |

| Ejection stroke | mm | 140 | 160 | 200 | 250 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 450 | 450 | |

| Slide speed | Down | mm/s | 40 | 40 | 100 | 100 | 100 | 120 | 120 | 120 | 120 | 120 | 120 | 150 | 150 |

| Pressing | mm/s | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | 8~15 | |

| Return | mm/s | 60 | 60 | 80 | 80 | 80 | 80 | 90 | 80 | 80 | 80 | 100 | 120 | 120 | |

| Table size | Left-right | mm | 350 | 450 | 600 | 800 | 800 | 800 | 1200 | 1400 | 1600 | 1600 | 1800 | 1800 | 2000 |

| Front-back | mm | 350 | 420 | 600 | 700 | 800 | 800 | 1200 | 1400 | 1600 | 1600 | 1600 | 1600 | 2000 | |

| Overall dimensions | Left-right | mm | 1200 | 1300 | 2000 | 2200 | 2200 | 2200 | 3300 | 3500 | 3700 | 3700 | 4000 | 4200 | 4500 |

| Front-back | mm | 700 | 800 | 1000 | 1000 | 1200 | 1200 | 1600 | 1600 | 1800 | 1800 | 1800 | 2000 | 2000 | |

| Height | mm | 1930 | 2350 | 3200 | 3300 | 3500 | 3700 | 4800 | 5000 | 5300 | 5700 | 5800 | 6000 | 6500 | |

| Motor power | KW | 3 | 5.5 | 7.5 | 15 | 18.5 | 18.5 | 22 | 37 | 37 | 44 | 60 | 90 | 134 | |

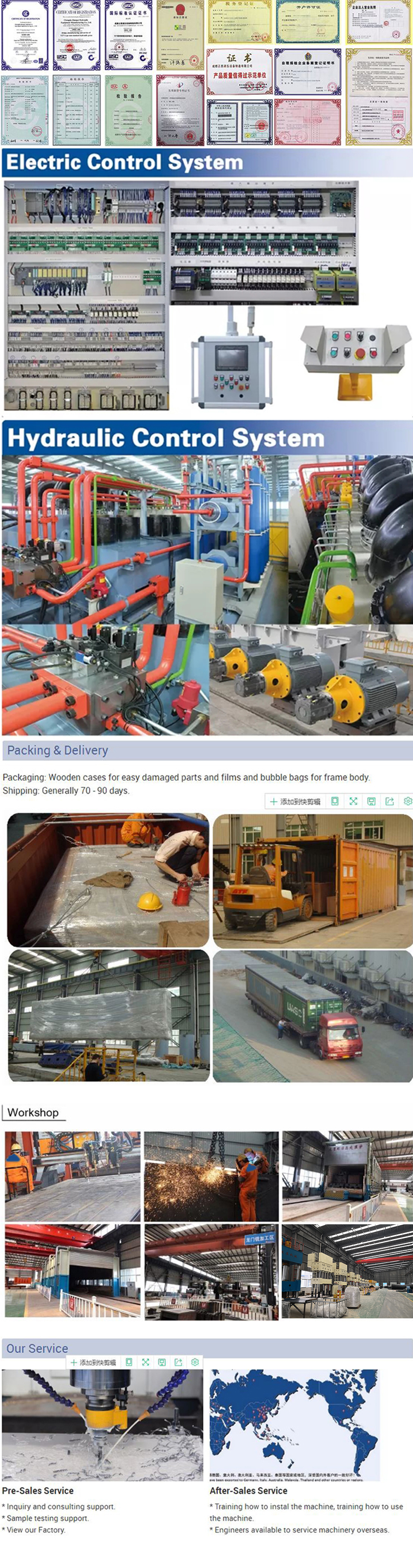

Certificate

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Jiaomei City ,Fujian Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : 4 Post Hydraulic Press > Hydraulic Press For Head Cover