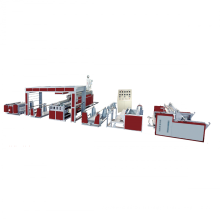

Complete Automatic PVC Coated Gypsum Ceiling Board Tile Production Line with Cutting and Packing Machine

Product Description

Product Description Product Application

4 Million sqm PVC Laminated Gypsum Suspended Ceiling Board Tile Making Machine with Cutting, Packing Machine

Mobile: +8618032163245 (wechat/whatsapp) The Lamination machine is used to paste decorative films like PVC film, aluminum foil etc with board (gypsum board or other board)together. Our latest Technology of full automatic ceiling production line and double side lamination line is very popular in domestic and international market. It is high automatic, saves manpower.

The finished PVC gypsum ceiling tile is made of paper-faced gypsum board with a layer of PVC on surface and aluminum foil on its back. It is a environmental friendly, light weight, high quality, fireproof, waterproof and corrosion-resistant decorative ceiling board. It can be widely used in high fireproof and waterproof requirement environment, such as hotel, hospital, school, house and factory etc.

Features of this Gypsum Ceiling Tile Production Line

1) Different automatic levels for your choice.

2) Adopting world famous brand Siemens PLC control system.

3) High capacity of 4-8 million sqm per year.

4) Raw materials: Gypsum board, PVC film, Aluminum foil, glue

5) Effective laminating width: Max 1300mm

6) Sheet thickness: 5--30mm

7) Laminating speed: Max 15m/min

8) Speed adjust way: frequency conversion synchronous speed regulating

9) Certification: ISO9001, SGS, CE, ROHS

The Full Laminating Line includes the following machines:

1. Automatic Board Loading machine

2. PVC film coating and laminating machine

3. Automatic board over turner

4. Aluminum foil coating laminating machine

5. Cutting machine

6. Edge wrapping machine

7. Packing machine

8. Finished board stacking

Flowchart of full line (some of the parts are optional)

Automatic board feeding--predusting--coating--drying and conveying--aluminium foil unwinding--pneumatic lamination for film and gypsum board--cutting(manual, automatic)-conveying --automatic overturn--coating--drying and conveying--PVC film unwinding--pneumatic lamination for film and gypsum board--cutting(manual, automatic)--drying and conveying--lengthwise cutting(dedusting)--horizontal cutting(dedusting)--belt conveyor ouput--autolift stacking conveying--edge wrapping--stretch packing--conveying--lift(finished products stacking)

Detailed Images

Detailed Images  Machine Parts Name: Glue Coating Machine

Machine Parts Name: Glue Coating Machine

Brand: Lvjoe

Original: Hebei, China

Glue coating rubber roller is made of #45 seamless steel with special rubber surface. Diameter is 180mm.

Glue coating steel roller adopts 45# seamless steel tube, with chrome plated surface finishing. Diameter is 156mm. Part Name: Laminating Machine

1. PVC film and aluminum foil unwinding part

Max unwinding diameter: 600mm

Unwinding part with the installation of manual tension control of friction, to control unwinding tension. Magnetic powder tension controller is available if you need.

Unwinding roller adopts 76mm pneumatic roller.

2. Lamination part

this part have two group of pressing. Each group equips with upper roller and lower roller to achieve the pressing effect. Upper roller is controlled by pneumatic cylinder. Working pressure is 4kg.

Machine Parts Name: Automatic Gypsum Board Over-turner

Machine Parts Name: Automatic Gypsum Board Over-turner

Brand: Lvjoe

Original: Hebei, China

Name: Automatic cutting machine

Brand: LVJOE

Size of fnished board: normal 603*603, 595*595mm other size available

Cutting speed: 15m/min

Cutting knife: three in portrait, five in lateral

Overall power: 17.15KW

Name: Rotary Type Edge Sealing Machine

Brand: LVJOE

Board Size: 603*603, 595*595mm

Packing speed: 6--8 pcs/minute

Electrical control: PLC

Install power: 4.5KW

Machine dimension: 4500*1600*1400

Weight: 900kg

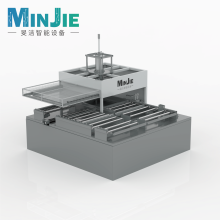

Finished Ceiling Tile Thermoplastic Packing Machine

Power: 23KW, 380V

Speed: 500 packs/hour

Standard packing temperature: 160-180C

Suitable film: PE, PUT

Finished board Stacking and Packing Machine

Stacking Layer: 10 layers (4 packages/layer)

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Related Products

Light Weight EPS Sandwich Panel Machine Production Line 91.8% Response Rate Lvjoe Brand Gypsum Board, Calcium Silicate Board Perforation Machine 91.8% Response Rate 5 Million sqm Calcium Silicate Board Making Equipment Manufacturer 91.8% Response Rate Contact us if you need more details on gypsum board laminated cutting machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vinyl laminating machine gypsum board Lamination Machine、gypsum board board lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Light Weight EPS Sandwich Panel Machine Production Line 91.8% Response Rate Lvjoe Brand Gypsum Board, Calcium Silicate Board Perforation Machine 91.8% Response Rate 5 Million sqm Calcium Silicate Board Making Equipment Manufacturer 91.8% Response Rate Contact us if you need more details on gypsum board laminated cutting machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vinyl laminating machine gypsum board Lamination Machine、gypsum board board lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

4 Million sqm PVC Laminated Gypsum Suspended Ceiling Board Tile Making Machine with Cutting, Packing Machine

Mobile: +8618032163245 (wechat/whatsapp) The Lamination machine is used to paste decorative films like PVC film, aluminum foil etc with board (gypsum board or other board)together. Our latest Technology of full automatic ceiling production line and double side lamination line is very popular in domestic and international market. It is high automatic, saves manpower.

The finished PVC gypsum ceiling tile is made of paper-faced gypsum board with a layer of PVC on surface and aluminum foil on its back. It is a environmental friendly, light weight, high quality, fireproof, waterproof and corrosion-resistant decorative ceiling board. It can be widely used in high fireproof and waterproof requirement environment, such as hotel, hospital, school, house and factory etc.

Features of this Gypsum Ceiling Tile Production Line

1) Different automatic levels for your choice.

2) Adopting world famous brand Siemens PLC control system.

3) High capacity of 4-8 million sqm per year.

4) Raw materials: Gypsum board, PVC film, Aluminum foil, glue

5) Effective laminating width: Max 1300mm

6) Sheet thickness: 5--30mm

7) Laminating speed: Max 15m/min

8) Speed adjust way: frequency conversion synchronous speed regulating

9) Certification: ISO9001, SGS, CE, ROHS

The Full Laminating Line includes the following machines:

1. Automatic Board Loading machine

2. PVC film coating and laminating machine

3. Automatic board over turner

4. Aluminum foil coating laminating machine

5. Cutting machine

6. Edge wrapping machine

7. Packing machine

8. Finished board stacking

Flowchart of full line (some of the parts are optional)

Automatic board feeding--predusting--coating--drying and conveying--aluminium foil unwinding--pneumatic lamination for film and gypsum board--cutting(manual, automatic)-conveying --automatic overturn--coating--drying and conveying--PVC film unwinding--pneumatic lamination for film and gypsum board--cutting(manual, automatic)--drying and conveying--lengthwise cutting(dedusting)--horizontal cutting(dedusting)--belt conveyor ouput--autolift stacking conveying--edge wrapping--stretch packing--conveying--lift(finished products stacking)

Detailed Images

Detailed Images  Machine Parts Name: Glue Coating Machine

Machine Parts Name: Glue Coating MachineBrand: Lvjoe

Original: Hebei, China

Glue coating rubber roller is made of #45 seamless steel with special rubber surface. Diameter is 180mm.

Glue coating steel roller adopts 45# seamless steel tube, with chrome plated surface finishing. Diameter is 156mm. Part Name: Laminating Machine

1. PVC film and aluminum foil unwinding part

Max unwinding diameter: 600mm

Unwinding part with the installation of manual tension control of friction, to control unwinding tension. Magnetic powder tension controller is available if you need.

Unwinding roller adopts 76mm pneumatic roller.

2. Lamination part

this part have two group of pressing. Each group equips with upper roller and lower roller to achieve the pressing effect. Upper roller is controlled by pneumatic cylinder. Working pressure is 4kg.

Machine Parts Name: Automatic Gypsum Board Over-turner

Machine Parts Name: Automatic Gypsum Board Over-turnerBrand: Lvjoe

Original: Hebei, China

Name: Automatic cutting machine

Brand: LVJOE

Size of fnished board: normal 603*603, 595*595mm other size available

Cutting speed: 15m/min

Cutting knife: three in portrait, five in lateral

Overall power: 17.15KW

Name: Rotary Type Edge Sealing Machine

Brand: LVJOE

Board Size: 603*603, 595*595mm

Packing speed: 6--8 pcs/minute

Electrical control: PLC

Install power: 4.5KW

Machine dimension: 4500*1600*1400

Weight: 900kg

Finished Ceiling Tile Thermoplastic Packing Machine

Power: 23KW, 380V

Speed: 500 packs/hour

Standard packing temperature: 160-180C

Suitable film: PE, PUT

Finished board Stacking and Packing Machine

Stacking Layer: 10 layers (4 packages/layer)

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Related Products

Light Weight EPS Sandwich Panel Machine Production Line 91.8% Response Rate Lvjoe Brand Gypsum Board, Calcium Silicate Board Perforation Machine 91.8% Response Rate 5 Million sqm Calcium Silicate Board Making Equipment Manufacturer 91.8% Response Rate Contact us if you need more details on gypsum board laminated cutting machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vinyl laminating machine gypsum board Lamination Machine、gypsum board board lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Light Weight EPS Sandwich Panel Machine Production Line 91.8% Response Rate Lvjoe Brand Gypsum Board, Calcium Silicate Board Perforation Machine 91.8% Response Rate 5 Million sqm Calcium Silicate Board Making Equipment Manufacturer 91.8% Response Rate Contact us if you need more details on gypsum board laminated cutting machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about vinyl laminating machine gypsum board Lamination Machine、gypsum board board lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lamination Machine

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery