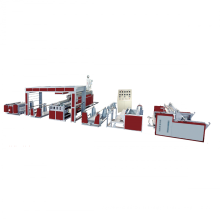

Hot Sale Facade Wall Panel Make Machine /Gypsume Board Laminating Production Line

Product Description

Product Description Gypsum board Lamination machine is to laminate fiber glass, paper, PVC film and aluminum foil on gypsum board,the finished products can be used as ceiling tile and partition wall panel. Product Application:

1.Gypsum Board Laminating Machine is to laminate PVC film and aluminum film on two sides of paper gypsum board, with the features of highly waterproof, moisture proof, flame-resist, heat-resist, warm-keeping, radiation proof, anti-sagging, non-deformed and so on. 2.Gypsum Board Laminating Machine is not only well- shaped, high intensity, durable in use, non-poisonous, but also good for adjusting inside room temperature, and keeping health for human being. No doubt it is an ideal green construction material, which is commonly used in public area, such as shopping mall, station, and casino. It is not a kind of art, but excel as art. elegant in design, unique in pattern.

Technical parameters:

Technical parameters:

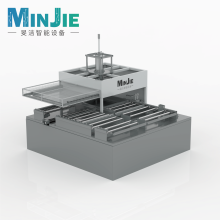

Packaging & Shipping 1.Automatic gypsum board feeding machine

The cylinder push the gypsum board that above on the stack lift platform to the conveyor roll, Ready to laminate PVC and aluminum film

Max. Load-bearing: 3000kg

Stroke: 1500mm

Min. Height: 620mm

Max. Height: 2000mm

Platform size: 1200*2400mm

2.Double sided laminating machine

Effective lamination width: ≤ 1300mm

Thickness of sheet: 5-30mm

Lamination speed: 3-15m/min

Board feeding and releasing mode: automatic

3.Automatic cutting machine

Consist of two sets cutting system: vertical/longitudinal cutting and horizontal cutting, equipped dust collector system.

Cut the 1.2*2.4m big board to the 603*603mm/595*595mm small board.

Cutting speed: 15m/min

Cutting knife: vertical/longitudinal:3 blades; horizontal : 5 blades

Overall power: 17.15KW

4.Automatic Edge sealing machine

Control by the PLC, high speed, high output, edging tight and firm.

Sheet size: 600*600mm

Production speed: 25pieces/min

Electrical control: PLC

Installed power: 5 KW

5.Automatic thermoplastic packing machine

Suitable for packing of PVC gypsum board finished product. The package id tight and smooth

Electric source: 380V

Power: 23KW

Speed: 500packs/hour

Standard packing temperature: 160-180℃

Package material: PE heat shrinking film.

Certifications

Certifications  Related Products 1

Related Products 1  Contact way zizi li Email: lvjoe01 AT china-machines.com.CN Wechat: 17732172215(WhatSApp/Telephone) Skype : +86 16630111157 ADD: 17th, NanYan Road Economical and Technological Development Zone,Shijiazhuang City,Hebei,China

Contact way zizi li Email: lvjoe01 AT china-machines.com.CN Wechat: 17732172215(WhatSApp/Telephone) Skype : +86 16630111157 ADD: 17th, NanYan Road Economical and Technological Development Zone,Shijiazhuang City,Hebei,China

Contact us if you need more details on gypsum board production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Facade Wall Panel、gypsum board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on gypsum board production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Facade Wall Panel、gypsum board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Gypsum Board Laminating Machine is to laminate PVC film and aluminum film on two sides of paper gypsum board, with the features of highly waterproof, moisture proof, flame-resist, heat-resist, warm-keeping, radiation proof, anti-sagging, non-deformed and so on. 2.Gypsum Board Laminating Machine is not only well- shaped, high intensity, durable in use, non-poisonous, but also good for adjusting inside room temperature, and keeping health for human being. No doubt it is an ideal green construction material, which is commonly used in public area, such as shopping mall, station, and casino. It is not a kind of art, but excel as art. elegant in design, unique in pattern.

Technical parameters:

Technical parameters: | 10 layers(4packages/layer) | |

| lengthways:3 blades, horizontal: 5 blades | |

| length:56000mm width:9200mm | |

| Double side:laminate front side and back at the one time single side:laminate one side at one time |

The cylinder push the gypsum board that above on the stack lift platform to the conveyor roll, Ready to laminate PVC and aluminum film

Max. Load-bearing: 3000kg

Stroke: 1500mm

Min. Height: 620mm

Max. Height: 2000mm

Platform size: 1200*2400mm

2.Double sided laminating machine

Effective lamination width: ≤ 1300mm

Thickness of sheet: 5-30mm

Lamination speed: 3-15m/min

Board feeding and releasing mode: automatic

3.Automatic cutting machine

Consist of two sets cutting system: vertical/longitudinal cutting and horizontal cutting, equipped dust collector system.

Cut the 1.2*2.4m big board to the 603*603mm/595*595mm small board.

Cutting speed: 15m/min

Cutting knife: vertical/longitudinal:3 blades; horizontal : 5 blades

Overall power: 17.15KW

4.Automatic Edge sealing machine

Control by the PLC, high speed, high output, edging tight and firm.

Sheet size: 600*600mm

Production speed: 25pieces/min

Electrical control: PLC

Installed power: 5 KW

5.Automatic thermoplastic packing machine

Suitable for packing of PVC gypsum board finished product. The package id tight and smooth

Electric source: 380V

Power: 23KW

Speed: 500packs/hour

Standard packing temperature: 160-180℃

Package material: PE heat shrinking film.

Certifications

Certifications  Related Products 1

Related Products 1  Contact way zizi li Email: lvjoe01 AT china-machines.com.CN Wechat: 17732172215(WhatSApp/Telephone) Skype : +86 16630111157 ADD: 17th, NanYan Road Economical and Technological Development Zone,Shijiazhuang City,Hebei,China

Contact way zizi li Email: lvjoe01 AT china-machines.com.CN Wechat: 17732172215(WhatSApp/Telephone) Skype : +86 16630111157 ADD: 17th, NanYan Road Economical and Technological Development Zone,Shijiazhuang City,Hebei,China

Contact us if you need more details on gypsum board production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Facade Wall Panel、gypsum board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on gypsum board production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Facade Wall Panel、gypsum board production line. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lamination Machine

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery