PVC laminated gypsum ceiling tile machine production line

Product Description

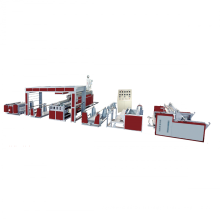

Product Description This model adopts latest double sides coating and laminating technology, synchronous coating and gluing the front( such as PVC) and the reverse side (such as aluminium foils)at the same time, without turn-over. Gypsum board lamination machine is to laminate film on gypsum board,the whole machine is in a synchronous way. 1.Capacity: 7000-12000m2 per day (basis of calculation: L:595mm, T:7mm, W:595mm, weight: 5.5 kg/M2, for 7mm board) 2.Automation simple and high degree automatic 3.Main materials Gypsum board , PVC film, aluminum foil, glue for PVC, glue for aluminum 4.Dimension of product Length*Width:595*595mm,600*600mm,603*603mm,1200*600mm Thickness:7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm

Product Description This model adopts latest double sides coating and laminating technology, synchronous coating and gluing the front( such as PVC) and the reverse side (such as aluminium foils)at the same time, without turn-over. Gypsum board lamination machine is to laminate film on gypsum board,the whole machine is in a synchronous way. 1.Capacity: 7000-12000m2 per day (basis of calculation: L:595mm, T:7mm, W:595mm, weight: 5.5 kg/M2, for 7mm board) 2.Automation simple and high degree automatic 3.Main materials Gypsum board , PVC film, aluminum foil, glue for PVC, glue for aluminum 4.Dimension of product Length*Width:595*595mm,600*600mm,603*603mm,1200*600mm Thickness:7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm  Lamination machine technical parameters:

Lamination machine technical parameters: Model | LV--1300SFM01 LV--1300SFM02 LV--1300SFM03 |

Max. laminating width | 1300mm |

Thickness of sheet | 5----30mm |

Max. Laminating Speed | 15m/min |

Speed Regulation | Frequency conversion synchronous speed regulating |

installed power | 8kw 10kw 20kw |

2. Automatic feeding machine 1. push-type 2. suction-type Two types for choice Cylinder push, photoelectric control, Max.Cylinder range 700mm. Through the push board platform rubber roller rolling transmission to accelerate speed,with the feature of low cost,economic and affordable (comparing to the suction type),easy to operate,fully automatic feeding.

2. Automatic feeding machine 1. push-type 2. suction-type Two types for choice Cylinder push, photoelectric control, Max.Cylinder range 700mm. Through the push board platform rubber roller rolling transmission to accelerate speed,with the feature of low cost,economic and affordable (comparing to the suction type),easy to operate,fully automatic feeding.  3. Automatic cutting machine This machine is used for cutting the laminated gypsum boards to a size of board according to saw gauge standard. First, put board to delivery roll, then come to the cutting system for the first time, and it turns to cutting system for the second time though delivery roll, then come to the board. It can be made a set of pulsed sack-duster for requirements.

3. Automatic cutting machine This machine is used for cutting the laminated gypsum boards to a size of board according to saw gauge standard. First, put board to delivery roll, then come to the cutting system for the first time, and it turns to cutting system for the second time though delivery roll, then come to the board. It can be made a set of pulsed sack-duster for requirements.  4. Automatic sealing machine right angle type gypsum board sealing machine This machine is a gypsum board ceiling decoration edging equipment, PLC photoelectric automatic control, high speed, high capacity. Edging tight and firm. Less investment in equipment and quick. It is a board(plasterboard), Hemming preferred equipment.

4. Automatic sealing machine right angle type gypsum board sealing machine This machine is a gypsum board ceiling decoration edging equipment, PLC photoelectric automatic control, high speed, high capacity. Edging tight and firm. Less investment in equipment and quick. It is a board(plasterboard), Hemming preferred equipment.  5. Automatic shrinking machine warm shrinking machine doing the heats shrinkable packaging for gypsum board after the completion of the sealing and cutting edge, using infrared ray heating for the film contraction. Specification: Packaging speed: 20m/minutes Weight: 500KG Packaging size: L1200*W700*H300mm Power : 18.75KW

5. Automatic shrinking machine warm shrinking machine doing the heats shrinkable packaging for gypsum board after the completion of the sealing and cutting edge, using infrared ray heating for the film contraction. Specification: Packaging speed: 20m/minutes Weight: 500KG Packaging size: L1200*W700*H300mm Power : 18.75KW  6.electrostatic pulse bag style dust collector 1. Usage: The machine is used in the dust collector of the automatic cutter of the laminated gypsum board.It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. 2. Machine composition: Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector motor,dust collector bag,dedusting frame,pulse controller.

6.electrostatic pulse bag style dust collector 1. Usage: The machine is used in the dust collector of the automatic cutter of the laminated gypsum board.It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. 2. Machine composition: Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector motor,dust collector bag,dedusting frame,pulse controller.  7. laminating pvc pictures show:

7. laminating pvc pictures show:  Our Services

Our Services  1) The machine guarantee1 years except the easy worn parts such as bearings, electric buttons. 2) Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to ensure the machine working well, each year we will send engineer to check and develop the technology. Packaging & Shipping Standard package for exporting or as your request.

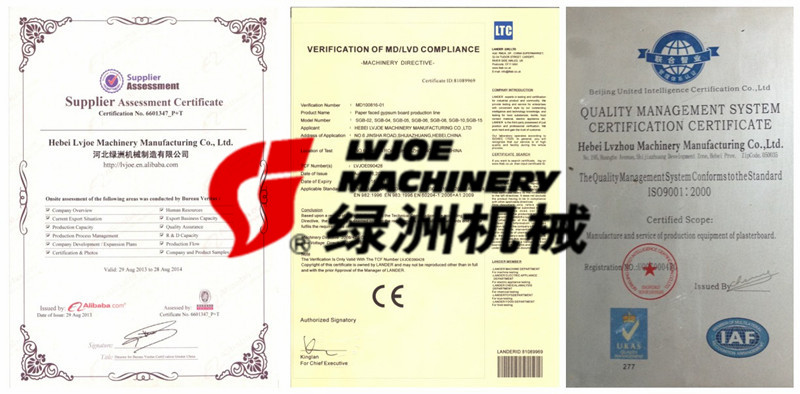

1) The machine guarantee1 years except the easy worn parts such as bearings, electric buttons. 2) Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to ensure the machine working well, each year we will send engineer to check and develop the technology. Packaging & Shipping Standard package for exporting or as your request.  Company Information Established in 1998. A large manufacturer of integrated supply dedicated in researching,manufacturing, trading of building material machinery and construction materials . CE approved by the EU ISO 9001 certificate professional team and rich experience, can give you the best price, the long service life

Company Information Established in 1998. A large manufacturer of integrated supply dedicated in researching,manufacturing, trading of building material machinery and construction materials . CE approved by the EU ISO 9001 certificate professional team and rich experience, can give you the best price, the long service life  Contact us if you need more details on PVC laminated gypsum ceiling tile machine production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum ceiling tile production line、PVC laminated ceiling tile machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on PVC laminated gypsum ceiling tile machine production line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum ceiling tile production line、PVC laminated ceiling tile machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lamination Machine

Premium Related Products