SGS checking for plaster board making machine

Product Description

Notion please our equipment could design for customer requirment, We have different grade, we have manual type , semi type, and fully automatic, the important thing: we add the sealing edge system in the production line,can save many persons, our line speed up now, can get 22m per min. and you can point your brand for the spears, such as,bears, PLC,motor and so on. We have been successful to set up the line for the world customer. Welcome to visit my factory, we have the running line and the sample line.

Notion please our equipment could design for customer requirment, We have different grade, we have manual type , semi type, and fully automatic, the important thing: we add the sealing edge system in the production line,can save many persons, our line speed up now, can get 22m per min. and you can point your brand for the spears, such as,bears, PLC,motor and so on. We have been successful to set up the line for the world customer. Welcome to visit my factory, we have the running line and the sample line.

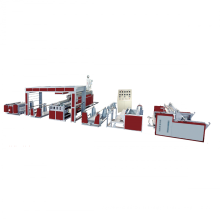

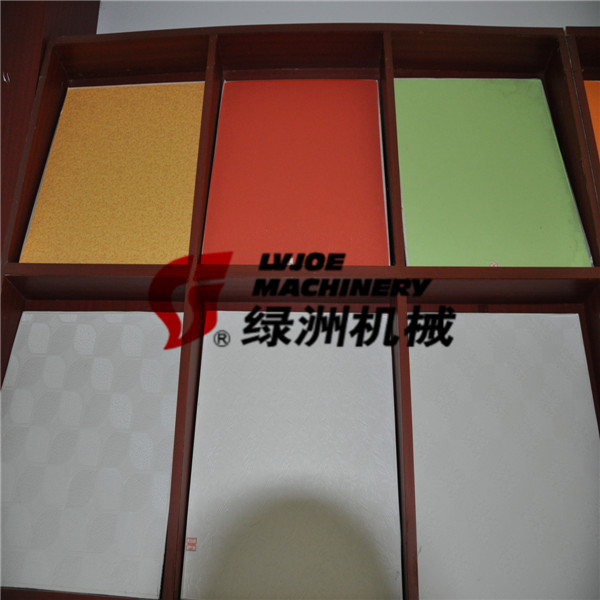

Main system introduction The lamination system We have two types for the lamination system,one side and double side lamination This is one side This is double side

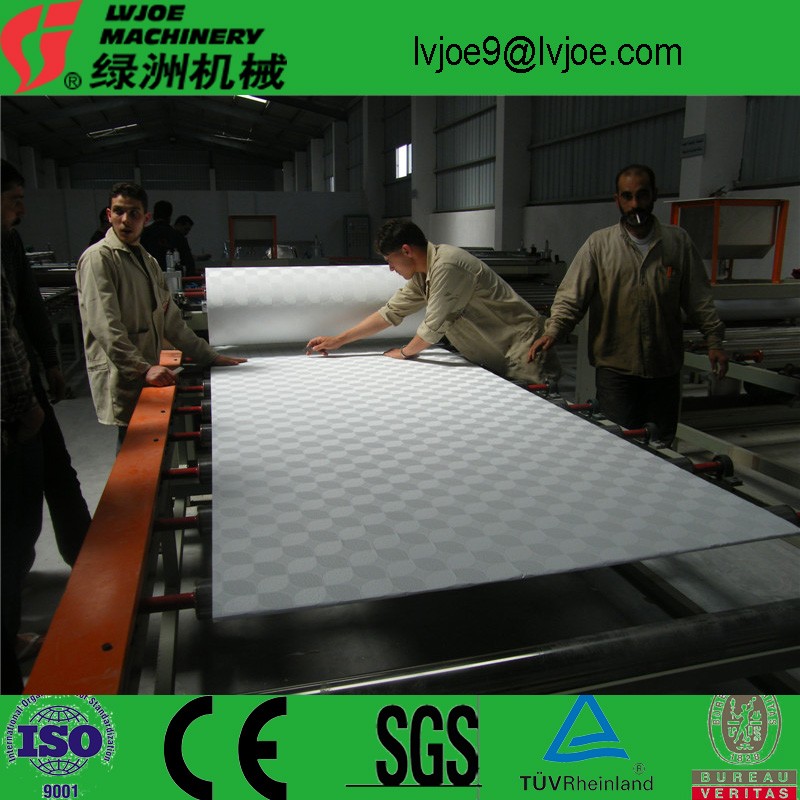

Main system introduction The lamination system We have two types for the lamination system,one side and double side lamination This is one side This is double side  The Lamination machine is used to paste the decorative film and boards together. First, put the board on the rollers. After the dust collection process, coat the glue on the boards, the glue will be qualitatived after conveying on the guide rollers. Then it will be combined with the film and enters into the recombination mechanism. After passing and cyclic rolling of the two lines of press roller, pinch roller and forming roller, the recombination is finished. The machine is fit for the surface decorative materials, such as pasted and compound decorative film and decorative paper, etc of the PVC baseboard, profile, low foaming board and wood board, etc

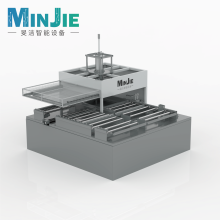

The Lamination machine is used to paste the decorative film and boards together. First, put the board on the rollers. After the dust collection process, coat the glue on the boards, the glue will be qualitatived after conveying on the guide rollers. Then it will be combined with the film and enters into the recombination mechanism. After passing and cyclic rolling of the two lines of press roller, pinch roller and forming roller, the recombination is finished. The machine is fit for the surface decorative materials, such as pasted and compound decorative film and decorative paper, etc of the PVC baseboard, profile, low foaming board and wood board, etc  . Specification: Max lamination width: 1600mm Max lamination speed:2-15m/min The thickness of the laminated board: 2—50mm Transmit power: 4.50kw Power: 380V,50HZ(can be made according to the inquiry) Size: 12600*1950*1600 Electrical control system:PLC system The cutting system We update our saw and technology to get the perfect board edge after cut The machine is used for cutting the laminated gypsum boards to be certain small pieces which are going to be used in the decoration. First, put the boards on the conveying rollers, then go to the first cutting device. After passing the second cutting device, the board will be formed. Specification: Max cutting: 1220*2440mm Max cutting speed: 15m/min Cutter allocation: three in vertical, five in transverse Transmit power: 17.15 KW Power: 380V(50hz) (can be made according to the inquiry) Size: (Length*Width*Hight) 9000*4200*1400mm Electrical control system:PLC system

. Specification: Max lamination width: 1600mm Max lamination speed:2-15m/min The thickness of the laminated board: 2—50mm Transmit power: 4.50kw Power: 380V,50HZ(can be made according to the inquiry) Size: 12600*1950*1600 Electrical control system:PLC system The cutting system We update our saw and technology to get the perfect board edge after cut The machine is used for cutting the laminated gypsum boards to be certain small pieces which are going to be used in the decoration. First, put the boards on the conveying rollers, then go to the first cutting device. After passing the second cutting device, the board will be formed. Specification: Max cutting: 1220*2440mm Max cutting speed: 15m/min Cutter allocation: three in vertical, five in transverse Transmit power: 17.15 KW Power: 380V(50hz) (can be made according to the inquiry) Size: (Length*Width*Hight) 9000*4200*1400mm Electrical control system:PLC system  Dust collection The machine is used in the dust collector of the automatic cutter of the laminated gypsum board. It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. Power of the dust collector: 15kw The machine mainly includes: one set of the dust collector shelf and host machine, one set of the dust exhaust pipe, one set of the dust exhaust fan and one set of the dust exhaust bag

Dust collection The machine is used in the dust collector of the automatic cutter of the laminated gypsum board. It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. Power of the dust collector: 15kw The machine mainly includes: one set of the dust collector shelf and host machine, one set of the dust exhaust pipe, one set of the dust exhaust fan and one set of the dust exhaust bag  The sealing system

The sealing system  The packing system

The packing system  Our customer case

Our customer case  1Saudi Arabia 20 million sqm gypsum board production line Whole line

1Saudi Arabia 20 million sqm gypsum board production line Whole line2 Saudi Arabia 2 million fully autoatic gypsum board lamination production line and 2 illion semi gysum board lamination

3 Shandong Juyuan Building Material Development Co.,Ltd 30 million sqm gypsum board production line Mixer Desulfurized gypsum/Coal/ Hot air type

4 Qatar 8 million sqm gypsum board production line and 2 million gypsum board Lamination Machine

5 Zhangjiakou 50,000 Tons gypsum powder production line Whole line Desulfurized gypsum/CoalJason Gypsum Board 6Group 30 Million sqm gypsum board production line Dryer, forming machine ant wet section Desulfurized gypsum/ Hot air type and 2million gypsum board lamination machine

7Xingzhou Mining Industry Co., Ltd 300,000 Tons Gypsum powder production line Whole line Natural gypsum/Coal/Hot air

8Handan State Grid 20 Million sqm Gypsum board production line Whole line Desulfurized gypsum

9Handan State Grid 200,000 Tons Gypsum powder production line Whole line Desulfurized gypsum/Coal/Hot air

10Guizhou Imperial Crown 45 Million sqm Gypsum board production line Mixer and other single equipments Single equipments

11Shanxi Juyibao New Material Co., Ltd 2 million gypsum powder production line Whole line Desulfurized gypsum/Natural gas

12 Shanxi Juyibao New Material Co., Ltd 10 Million sqm gypsum board lamination line Whole line Desulfurized 13 iran 10 million gypsum board machine and 100 t thousand gypsum powder line and lamination line /Natural gas direct burning 14 tailand gypsum board line and gypsum powder line and gypsum board laination line 15 burma 5 million gypsum board machine and 30 t thousand per year gypsum powder machine and gypsum board lamination machine

Part (examples) | Product | Country of origin | Supplier | |

01. Bearings | SKF &FAG&KOYO&NSK HRB | Sweden&Germany&Japan |

|

|

02. Shaft |

| China |

| own product |

03. Motor | Siemens&ABB&TECO JIE BRAND | Germany&TaiWan |

|

|

04. Coupling | SKF &FALK | Germany&U.S.A |

|

|

05. Impeller |

| China |

| own product |

06. Casing |

| China |

| own product |

07.Belt | OPTI&MITSUBOSHI &BANDO | Germany&Japan |

|

|

08.Belt pulley | CPT | China |

|

|

09. REDUCER | SEW |

|

|

|

10.PLC | SIMMENS |

|

|

|

Product Categories : Lamination Machine

Premium Related Products