China Supplier drywall partition and ceiling lamination machine China Supplier drywall partition and ceiling lamination machine

Product Description

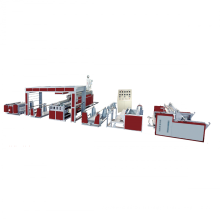

Product Description China Supplier drywall partition and ceiling Lamination machine Gypsum board laminating machine line: Gypsum board laminating machine line is to laminate film and board. Firstly, eliminate dust of board, which is on the feeding roller, then coat glue on the board. After it is feeding by means of guide roll, adhensive being fixed position and film go into composite structure. This process includes twice press roll, pinch roll and forming roll. This machine is used for film-coating PVC protective board, forming board, low-foaming board, wooden board etc. Technical specification: Max sheet width: 1300mm Max sheet speed: 2-15m/min Thickness of sheet: 2-50mm Power: 4.5kw Power supply: 380V, 50Hz Dimension: 12600*1950*1600  Gypsum board cutting machine: This machine is used for cutting the laminated gypsum boards to a size of board according to saw gauge standard. First, put board to delivery roll, then come to the cutting system for the first time, and it turns to cutting system for the second time though delivery roll, then come to the board. It can be made a set of pulsed sack-duster for requirements.

Gypsum board cutting machine: This machine is used for cutting the laminated gypsum boards to a size of board according to saw gauge standard. First, put board to delivery roll, then come to the cutting system for the first time, and it turns to cutting system for the second time though delivery roll, then come to the board. It can be made a set of pulsed sack-duster for requirements.  gypsum board Lamination Machine specification:

gypsum board Lamination Machine specification:

Required equipment:(4 million square meters per year, 16 hours per day and calculated for 300 days): 1.FM1300 PVC lamination machine one set; 2.FM1300 aluminum lamination machine one set; 3.Automatic cutter for the gypsum board lamination machine one set; 4.Electrostatic pulse bag style dust collector one set. PVC film lamination machine: Automatic board feeding machine: 1. push-type 2. suction-type Two types for choice Cylinder push, photoelectric control, Max.Cylinder range 700mm. Through the push board platform rubber roller rolling transmission to accelerate speed,with the feature of low cost,economic and affordable (comparing to the suction type),easy to operate,fully automatic feeding.

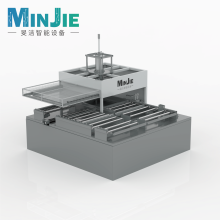

Automatic over-turning machine: It avoids the damage for the board by adjusting the angle of transfer board.

Automatic over-turning machine: It avoids the damage for the board by adjusting the angle of transfer board.  gypsum board side sealing machine: 1.LV-BB01 gypsum board sealing machine(type:01,02,03) This product adopts overseas advanced rotary edging technology, as well as the advantage of right-angle edging. It adopts servo motor to control the plasterboard running and rotating, to achieve the high precision,beautiful edging,no joint. It is mainly used for the edging of high quality plasterboard. 2. LV-BB02 right angle type gypsum board sealing machine This machine is a gypsum board ceiling decoration edging equipment, PLC photoelectric automatic control, high speed, high capacity. Edging tight and firm. Less investment in equipment and quick. It is a board (plasterboard), Hemming preferred equipment.

gypsum board side sealing machine: 1.LV-BB01 gypsum board sealing machine(type:01,02,03) This product adopts overseas advanced rotary edging technology, as well as the advantage of right-angle edging. It adopts servo motor to control the plasterboard running and rotating, to achieve the high precision,beautiful edging,no joint. It is mainly used for the edging of high quality plasterboard. 2. LV-BB02 right angle type gypsum board sealing machine This machine is a gypsum board ceiling decoration edging equipment, PLC photoelectric automatic control, high speed, high capacity. Edging tight and firm. Less investment in equipment and quick. It is a board (plasterboard), Hemming preferred equipment.  gypsum board glue coating nose machine: Rubber roller has the feature of Corrosion resistance, acid and alkai resistance, oil resistance. It is made of 45# seamless steel tube( the surface is special rubber). Diameter is 180mm. Axial plane beating quantity:0.05mm. Glue coating steel roller adopts 45# seamless steel tube. with Chrome plated surface finishing. Diameter is 156mm. Axial plane beating quantity:0.004mm.

gypsum board glue coating nose machine: Rubber roller has the feature of Corrosion resistance, acid and alkai resistance, oil resistance. It is made of 45# seamless steel tube( the surface is special rubber). Diameter is 180mm. Axial plane beating quantity:0.05mm. Glue coating steel roller adopts 45# seamless steel tube. with Chrome plated surface finishing. Diameter is 156mm. Axial plane beating quantity:0.004mm.  electrostatic pulse bag style dust collector: 1. Usage: The machine is used in the dust collector of the automatic cutter of the laminated gypsum board.It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. 2. Machine composition: Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector motor,dust collector bag,dedusting frame,pulse controller. Controlling system of production line: We adopt GSM and Mitsubishi latest QU series CPU as main component for improving significantly the automation level of production line.

electrostatic pulse bag style dust collector: 1. Usage: The machine is used in the dust collector of the automatic cutter of the laminated gypsum board.It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. 2. Machine composition: Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector motor,dust collector bag,dedusting frame,pulse controller. Controlling system of production line: We adopt GSM and Mitsubishi latest QU series CPU as main component for improving significantly the automation level of production line.

Contact us if you need more details on China Supplier drywall partition and ceiling lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum board ceiling board lamination machine、house design plasterboard lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on China Supplier drywall partition and ceiling lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum board ceiling board lamination machine、house design plasterboard lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Gypsum board cutting machine: This machine is used for cutting the laminated gypsum boards to a size of board according to saw gauge standard. First, put board to delivery roll, then come to the cutting system for the first time, and it turns to cutting system for the second time though delivery roll, then come to the board. It can be made a set of pulsed sack-duster for requirements.

Gypsum board cutting machine: This machine is used for cutting the laminated gypsum boards to a size of board according to saw gauge standard. First, put board to delivery roll, then come to the cutting system for the first time, and it turns to cutting system for the second time though delivery roll, then come to the board. It can be made a set of pulsed sack-duster for requirements.  gypsum board Lamination Machine specification:

gypsum board Lamination Machine specification: Sheet width | 1300mm |

Sheet thickness | 2-50mm |

Sheet speed | 2-15m/min |

Transmission power | 4.5kw |

Pneumatic working pressure | 4kg |

Weight | 2500kg |

Dimension | 12600*1950*1600mm |

Automatic over-turning machine: It avoids the damage for the board by adjusting the angle of transfer board.

Automatic over-turning machine: It avoids the damage for the board by adjusting the angle of transfer board.  gypsum board side sealing machine: 1.LV-BB01 gypsum board sealing machine(type:01,02,03) This product adopts overseas advanced rotary edging technology, as well as the advantage of right-angle edging. It adopts servo motor to control the plasterboard running and rotating, to achieve the high precision,beautiful edging,no joint. It is mainly used for the edging of high quality plasterboard. 2. LV-BB02 right angle type gypsum board sealing machine This machine is a gypsum board ceiling decoration edging equipment, PLC photoelectric automatic control, high speed, high capacity. Edging tight and firm. Less investment in equipment and quick. It is a board (plasterboard), Hemming preferred equipment.

gypsum board side sealing machine: 1.LV-BB01 gypsum board sealing machine(type:01,02,03) This product adopts overseas advanced rotary edging technology, as well as the advantage of right-angle edging. It adopts servo motor to control the plasterboard running and rotating, to achieve the high precision,beautiful edging,no joint. It is mainly used for the edging of high quality plasterboard. 2. LV-BB02 right angle type gypsum board sealing machine This machine is a gypsum board ceiling decoration edging equipment, PLC photoelectric automatic control, high speed, high capacity. Edging tight and firm. Less investment in equipment and quick. It is a board (plasterboard), Hemming preferred equipment.  gypsum board glue coating nose machine: Rubber roller has the feature of Corrosion resistance, acid and alkai resistance, oil resistance. It is made of 45# seamless steel tube( the surface is special rubber). Diameter is 180mm. Axial plane beating quantity:0.05mm. Glue coating steel roller adopts 45# seamless steel tube. with Chrome plated surface finishing. Diameter is 156mm. Axial plane beating quantity:0.004mm.

gypsum board glue coating nose machine: Rubber roller has the feature of Corrosion resistance, acid and alkai resistance, oil resistance. It is made of 45# seamless steel tube( the surface is special rubber). Diameter is 180mm. Axial plane beating quantity:0.05mm. Glue coating steel roller adopts 45# seamless steel tube. with Chrome plated surface finishing. Diameter is 156mm. Axial plane beating quantity:0.004mm.  electrostatic pulse bag style dust collector: 1. Usage: The machine is used in the dust collector of the automatic cutter of the laminated gypsum board.It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. 2. Machine composition: Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector motor,dust collector bag,dedusting frame,pulse controller. Controlling system of production line: We adopt GSM and Mitsubishi latest QU series CPU as main component for improving significantly the automation level of production line.

electrostatic pulse bag style dust collector: 1. Usage: The machine is used in the dust collector of the automatic cutter of the laminated gypsum board.It equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. 2. Machine composition: Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector motor,dust collector bag,dedusting frame,pulse controller. Controlling system of production line: We adopt GSM and Mitsubishi latest QU series CPU as main component for improving significantly the automation level of production line.

Contact us if you need more details on China Supplier drywall partition and ceiling lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum board ceiling board lamination machine、house design plasterboard lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on China Supplier drywall partition and ceiling lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum board ceiling board lamination machine、house design plasterboard lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lamination Machine

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery