Building material low price interior wall panels making machine

Product Description

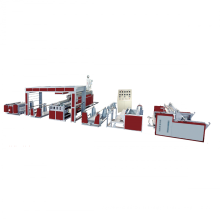

Gypsum board laminating machine line: Gypsum board laminating machine line is to laminate film and board. Firstly, eliminate dust of board, which is on the feeding roller, then coat glue on the board. After it is feeding by means of guide roll, adhensive being fixed position and film go into composite structure. This process includes twice press roll, pinch roll and forming roll. This machine is used for film-coating PVC protective board, forming board, low-foaming board, wooden board etc. Main features: Advanced edge alignment system, speed regulation, dust removal, glue coating. Technical specification: Max sheet width: 1300mm Max sheet speed: 2-15m/min Thickness of sheet: 2-50mm Power: 4.5kw Power supply: 380V, 50Hz Dimension: 12600*1950*1600 gypsum board Lamination machine specification:

Gypsum board laminating machine line: Gypsum board laminating machine line is to laminate film and board. Firstly, eliminate dust of board, which is on the feeding roller, then coat glue on the board. After it is feeding by means of guide roll, adhensive being fixed position and film go into composite structure. This process includes twice press roll, pinch roll and forming roll. This machine is used for film-coating PVC protective board, forming board, low-foaming board, wooden board etc. Main features: Advanced edge alignment system, speed regulation, dust removal, glue coating. Technical specification: Max sheet width: 1300mm Max sheet speed: 2-15m/min Thickness of sheet: 2-50mm Power: 4.5kw Power supply: 380V, 50Hz Dimension: 12600*1950*1600 gypsum board Lamination machine specification: Sheet width | 1300mm |

Sheet thickness | 2-50mm |

Sheet speed | 2-15m/min |

Transmission power | 4.5kw |

Pneumatic working pressure | 4kg |

Weight | 2500kg |

Dimension | 12600*1950*1600mm |

and firm. Less investment in equipment and quick. It is a board (plasterboard), Hemming preferred equipment.

and firm. Less investment in equipment and quick. It is a board (plasterboard), Hemming preferred equipment.

1. Our company has professional installation & debug teams. We will install and debug the production line at the customers' place until the equipment produces the qualified products. 2. We supply the accessories all the year round. The guarantee time of the equipment is one year.

1. Our company has professional installation & debug teams. We will install and debug the production line at the customers' place until the equipment produces the qualified products. 2. We supply the accessories all the year round. The guarantee time of the equipment is one year. 3. We are responsible for the technical consultation and service all the year around and solve all kinds of technical problems at any time.

4. We can help the customer to do the consignment and the relevant procedure for import and export.

5. Our company will supply the information of the seller for all kinds of raw material and relevant information. 6.If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms.

Contact us if you need more details on interior wall panels making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum board ceiling board lamination machine、house design plasterboard lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on interior wall panels making machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about gypsum board ceiling board lamination machine、house design plasterboard lamination machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lamination Machine

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery