gypsum board laminated sheet with PVC film production line

Product Description

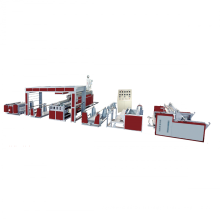

Specification 1 full-automatic,assembly line work 2 easy to install and operate 3 high efficiency,stable rate of production 4 energy saving,labor saving 5 ISO CE approved  Pls tell us your detailed requirements, we will design the most suitable line for you. Full-automatic Gypsum Board Lamination Production Machine Product Description Introduction and Usage: The laminating machine is used to paste the decorative film and boards Together. The films can be with the features of highly waterproof, moisture-proof, flame-resist, heat-resist, warm-keeping, radiation proof, anti-sagging, non-deformed and so on. Laminated gypsum board is not only well- shaped, high intensive, durable in use, non-poisonous, but also good for adjusting inside room temperature, and keeping health for human being. No doubt it is an ideal green construction material, which is commonly used in public area, such as shopping mall, station, and casino. It is not a kind of art, but excel as art. Elegant in design, unique in pattern. The machine is fit for the surface decorative materials, such as pasted and compound Decorative film and decorative paper, etc. The suitable boards include PVC baseboard, low foaming Board ,gypsum board, wood board, sectional boards, etc. Flowchart: Automatic board feeding——PVC film and Aluminum foil Laminating----Gypsum board cutting---edge sealing---packing----stacking Main components of this production line Automatic board loading device: The device is divided into suction-type and push-type. Suction-type adopts Single side suction way to feed kinds of plasterboard into the next production step. It can achieve the continuous production without hurting the board.Easy to operate with reliable performance. Push-type :Cylinder push, photoelectric control, Max. Cylinder range 700mm.Through the push board platform rubber roller rolling transmission to accelerate speed ,with the feature of low cost ,economic and affordable (comparing to the suction type),easy to operate, fully automatic feeding. suction-type Push-type Lamination machine Automatic over-turning machine Can save labor cost and improve efficiency. Cutting machine 1. Size of gypsum board :1220*2400mm 2. Size of finished gypsum board :600*600 3. Cutting speed :15m/min adjustable 4. Cutting knife : three in portrait, five in lateral Electrostatic pulse bag style dust collector corollary equipment of Cutting Machine. Provide a clean working environment. Usage: The machine is used in the dust collector of the automatic cutter of the laminate gypsum board, It is equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. Machine composition:Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector moto, dust collector bag, dedusting frame, pulse controller, etc. Finished board

Pls tell us your detailed requirements, we will design the most suitable line for you. Full-automatic Gypsum Board Lamination Production Machine Product Description Introduction and Usage: The laminating machine is used to paste the decorative film and boards Together. The films can be with the features of highly waterproof, moisture-proof, flame-resist, heat-resist, warm-keeping, radiation proof, anti-sagging, non-deformed and so on. Laminated gypsum board is not only well- shaped, high intensive, durable in use, non-poisonous, but also good for adjusting inside room temperature, and keeping health for human being. No doubt it is an ideal green construction material, which is commonly used in public area, such as shopping mall, station, and casino. It is not a kind of art, but excel as art. Elegant in design, unique in pattern. The machine is fit for the surface decorative materials, such as pasted and compound Decorative film and decorative paper, etc. The suitable boards include PVC baseboard, low foaming Board ,gypsum board, wood board, sectional boards, etc. Flowchart: Automatic board feeding——PVC film and Aluminum foil Laminating----Gypsum board cutting---edge sealing---packing----stacking Main components of this production line Automatic board loading device: The device is divided into suction-type and push-type. Suction-type adopts Single side suction way to feed kinds of plasterboard into the next production step. It can achieve the continuous production without hurting the board.Easy to operate with reliable performance. Push-type :Cylinder push, photoelectric control, Max. Cylinder range 700mm.Through the push board platform rubber roller rolling transmission to accelerate speed ,with the feature of low cost ,economic and affordable (comparing to the suction type),easy to operate, fully automatic feeding. suction-type Push-type Lamination machine Automatic over-turning machine Can save labor cost and improve efficiency. Cutting machine 1. Size of gypsum board :1220*2400mm 2. Size of finished gypsum board :600*600 3. Cutting speed :15m/min adjustable 4. Cutting knife : three in portrait, five in lateral Electrostatic pulse bag style dust collector corollary equipment of Cutting Machine. Provide a clean working environment. Usage: The machine is used in the dust collector of the automatic cutter of the laminate gypsum board, It is equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. Machine composition:Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector moto, dust collector bag, dedusting frame, pulse controller, etc. Finished board  Certification

Certification  Our Services 1) The machine guarantee1 years except the easy worn parts such as bearings, electric buttons. 2) Machine installation and commissioning: Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to guarantee the machine good running, each year we will send engineer to check and develop the technology. 5) If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms. Company Information Hebei Greens Building Material Technology Development Co., Ltd(a branch company of Lvjoe Group) is a large manufacturer of building material machinery. With the development of our company, we established Lvjoe Group in 2016. The Group set up a research and development center for gypsum board equipment, a gypsum board equipment manufacturing base, Hebei Greens Building Material Technology Development Co., Ltd. Greens company mainly manufactures gypsum board Lamination machine, mineral wool board production line, Fiber cement board production line, Mgo board production line, gypsum cornice production line, etc. If you want to know more about out company and machine , pls contact us without hesitation. Whatsapp: +8618032163245 Maisie Zhang Contact us if you need more details on aluminum foil gypsum board laminated production machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PVC foam board laminating machine、laminate flooring production machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 1) The machine guarantee1 years except the easy worn parts such as bearings, electric buttons. 2) Machine installation and commissioning: Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to guarantee the machine good running, each year we will send engineer to check and develop the technology. 5) If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms. Company Information Hebei Greens Building Material Technology Development Co., Ltd(a branch company of Lvjoe Group) is a large manufacturer of building material machinery. With the development of our company, we established Lvjoe Group in 2016. The Group set up a research and development center for gypsum board equipment, a gypsum board equipment manufacturing base, Hebei Greens Building Material Technology Development Co., Ltd. Greens company mainly manufactures gypsum board Lamination machine, mineral wool board production line, Fiber cement board production line, Mgo board production line, gypsum cornice production line, etc. If you want to know more about out company and machine , pls contact us without hesitation. Whatsapp: +8618032163245 Maisie Zhang Contact us if you need more details on aluminum foil gypsum board laminated production machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PVC foam board laminating machine、laminate flooring production machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Pls tell us your detailed requirements, we will design the most suitable line for you. Full-automatic Gypsum Board Lamination Production Machine Product Description Introduction and Usage: The laminating machine is used to paste the decorative film and boards Together. The films can be with the features of highly waterproof, moisture-proof, flame-resist, heat-resist, warm-keeping, radiation proof, anti-sagging, non-deformed and so on. Laminated gypsum board is not only well- shaped, high intensive, durable in use, non-poisonous, but also good for adjusting inside room temperature, and keeping health for human being. No doubt it is an ideal green construction material, which is commonly used in public area, such as shopping mall, station, and casino. It is not a kind of art, but excel as art. Elegant in design, unique in pattern. The machine is fit for the surface decorative materials, such as pasted and compound Decorative film and decorative paper, etc. The suitable boards include PVC baseboard, low foaming Board ,gypsum board, wood board, sectional boards, etc. Flowchart: Automatic board feeding——PVC film and Aluminum foil Laminating----Gypsum board cutting---edge sealing---packing----stacking Main components of this production line Automatic board loading device: The device is divided into suction-type and push-type. Suction-type adopts Single side suction way to feed kinds of plasterboard into the next production step. It can achieve the continuous production without hurting the board.Easy to operate with reliable performance. Push-type :Cylinder push, photoelectric control, Max. Cylinder range 700mm.Through the push board platform rubber roller rolling transmission to accelerate speed ,with the feature of low cost ,economic and affordable (comparing to the suction type),easy to operate, fully automatic feeding. suction-type Push-type Lamination machine Automatic over-turning machine Can save labor cost and improve efficiency. Cutting machine 1. Size of gypsum board :1220*2400mm 2. Size of finished gypsum board :600*600 3. Cutting speed :15m/min adjustable 4. Cutting knife : three in portrait, five in lateral Electrostatic pulse bag style dust collector corollary equipment of Cutting Machine. Provide a clean working environment. Usage: The machine is used in the dust collector of the automatic cutter of the laminate gypsum board, It is equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. Machine composition:Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector moto, dust collector bag, dedusting frame, pulse controller, etc. Finished board

Pls tell us your detailed requirements, we will design the most suitable line for you. Full-automatic Gypsum Board Lamination Production Machine Product Description Introduction and Usage: The laminating machine is used to paste the decorative film and boards Together. The films can be with the features of highly waterproof, moisture-proof, flame-resist, heat-resist, warm-keeping, radiation proof, anti-sagging, non-deformed and so on. Laminated gypsum board is not only well- shaped, high intensive, durable in use, non-poisonous, but also good for adjusting inside room temperature, and keeping health for human being. No doubt it is an ideal green construction material, which is commonly used in public area, such as shopping mall, station, and casino. It is not a kind of art, but excel as art. Elegant in design, unique in pattern. The machine is fit for the surface decorative materials, such as pasted and compound Decorative film and decorative paper, etc. The suitable boards include PVC baseboard, low foaming Board ,gypsum board, wood board, sectional boards, etc. Flowchart: Automatic board feeding——PVC film and Aluminum foil Laminating----Gypsum board cutting---edge sealing---packing----stacking Main components of this production line Automatic board loading device: The device is divided into suction-type and push-type. Suction-type adopts Single side suction way to feed kinds of plasterboard into the next production step. It can achieve the continuous production without hurting the board.Easy to operate with reliable performance. Push-type :Cylinder push, photoelectric control, Max. Cylinder range 700mm.Through the push board platform rubber roller rolling transmission to accelerate speed ,with the feature of low cost ,economic and affordable (comparing to the suction type),easy to operate, fully automatic feeding. suction-type Push-type Lamination machine Automatic over-turning machine Can save labor cost and improve efficiency. Cutting machine 1. Size of gypsum board :1220*2400mm 2. Size of finished gypsum board :600*600 3. Cutting speed :15m/min adjustable 4. Cutting knife : three in portrait, five in lateral Electrostatic pulse bag style dust collector corollary equipment of Cutting Machine. Provide a clean working environment. Usage: The machine is used in the dust collector of the automatic cutter of the laminate gypsum board, It is equipped with big sized dust exhaust fan and dust exhaust pipe. It can efficiently reach to the purpose of the dust exhausting. Machine composition:Dust collector frame, one set of main machine, one set of dust collector pipe, one set of dust collector moto, dust collector bag, dedusting frame, pulse controller, etc. Finished board  Certification

Certification  Our Services 1) The machine guarantee1 years except the easy worn parts such as bearings, electric buttons. 2) Machine installation and commissioning: Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to guarantee the machine good running, each year we will send engineer to check and develop the technology. 5) If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms. Company Information Hebei Greens Building Material Technology Development Co., Ltd(a branch company of Lvjoe Group) is a large manufacturer of building material machinery. With the development of our company, we established Lvjoe Group in 2016. The Group set up a research and development center for gypsum board equipment, a gypsum board equipment manufacturing base, Hebei Greens Building Material Technology Development Co., Ltd. Greens company mainly manufactures gypsum board Lamination machine, mineral wool board production line, Fiber cement board production line, Mgo board production line, gypsum cornice production line, etc. If you want to know more about out company and machine , pls contact us without hesitation. Whatsapp: +8618032163245 Maisie Zhang Contact us if you need more details on aluminum foil gypsum board laminated production machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PVC foam board laminating machine、laminate flooring production machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 1) The machine guarantee1 years except the easy worn parts such as bearings, electric buttons. 2) Machine installation and commissioning: Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the destination. 3)Our engineers will train the buyers' worker to operate the machine and after you master the machine then pay us the installation and commissioning payment. 4) In order to guarantee the machine good running, each year we will send engineer to check and develop the technology. 5) If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms. Company Information Hebei Greens Building Material Technology Development Co., Ltd(a branch company of Lvjoe Group) is a large manufacturer of building material machinery. With the development of our company, we established Lvjoe Group in 2016. The Group set up a research and development center for gypsum board equipment, a gypsum board equipment manufacturing base, Hebei Greens Building Material Technology Development Co., Ltd. Greens company mainly manufactures gypsum board Lamination machine, mineral wool board production line, Fiber cement board production line, Mgo board production line, gypsum cornice production line, etc. If you want to know more about out company and machine , pls contact us without hesitation. Whatsapp: +8618032163245 Maisie Zhang Contact us if you need more details on aluminum foil gypsum board laminated production machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PVC foam board laminating machine、laminate flooring production machines. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lamination Machine

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery