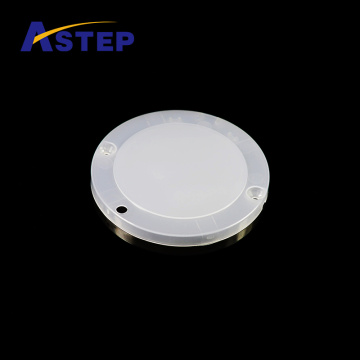

Custmized plastic Injection for electronic lighting

Basic Info

Model No.: plastic parts 001

Product Description

Customized Plastic injection case for electronics

Plastic injection parts are widely applicable to drivers, lightings,Electronic Products' shells,etc. We have 18 sets Haitian injection molding machines, 10 Engineers, Daily Capacity up to 200K pcs. Have rich experience in injection molding of high light, white and transparent products. ABS, PC, PC/ABS, PA, TPE, and all kinds of fiber reinforced material, injection molding process.

| Product Name | Customized plastic injection case for electronics |

| Material | ABS, PC, PC/ABS, PA, TPE |

| Color | White and black |

| Standard | DIN GB ISO JIS BA ANSI |

| Package | As Customer demands |

| Machine | Haitian injection molding machines |

| Shape | As customer's drawing |

| Used | Industry machinery |

Passed the ISO9001:2008 quality system authentication and ROHS authentication

Passed the IATF16949 quality system authentication and ROHS authentication.

Our metal spring workshop

Machine:Taiwan 620CNC spring machine

Machine Qty:30

Engineer:15

Daily Capacity:2KK pcs

0.08~3.0mm spring with different shape,Precision with 0.05mm

Our Stamping Workshop

Machine:Taiwan Xieyi punching machine

Machine Qty:42 (6T-200T)

Engineer:30

Daily Capacity:5KK pcs

Metal spring plate series,radiating fin series,

shielding cover series and mica sheet series.

Our Turning workshop

Machine:Taiwan Mingyang

CNC automatic lathes 15,CNC lathes 15

Engineer:10

Daily Capacity:300K pcs

External diameter 1.0~200mm of round bar, multiangle bar and multi spec.products.Precision between 0.005~0.01mm.

Machine:Haitian injection molding machine,

Machine Qty:18

Engineer:10

Daily Capacity:200K pcs

Rich experience in injection molding of high light,white and transparent products. ABS, PC, PC/ABS, PA,TPE, and all kinds of fiber reinforced material,injection molding process

Machine:Full automatic alluminum profile

cutting machine 8,CNC 6

Machine Qty:9

Engineer:15

Daily Capacity:100K pcs

Omnibearing processing procedures as a whole ,such as production,washing, chamfer, drilling and other hardware econdary operation

Q: Are you trading company or manufacturer ?

A: We are factory with more than 14 years experience in metal parts.We have our own factory, warehouse,machines and test equipment and good service.

Q: How long is your delivery time?

A: Generally it is 10 days if the samples approved . It is according to the order's quantity.

Q: How is the warranty of the products quality control?

A: We hold the quality controlling from very beginning to the end and aim at 100% error free.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Product Categories : Plastic Injection Parts