Factory Direct Prices Machines For Small Industries MGO Partition Board

Product Description

Product Description

Product Description  Factory Direct Prices Machines For Small Industries MGO Partition Board 1.The MgO board is environmental friendly, high fireproof and waterproof, can be painted, laminated. nailed and sawn. It is widely used for ceiling, wall panel, decorating of indoor wall and lining board for furniture.

Factory Direct Prices Machines For Small Industries MGO Partition Board 1.The MgO board is environmental friendly, high fireproof and waterproof, can be painted, laminated. nailed and sawn. It is widely used for ceiling, wall panel, decorating of indoor wall and lining board for furniture.MgO board can replace three-ply board, five-ply board, flakeboard, MDF (Medium Density Fiberboard ) and Gypsum Board. 2.MgO Board performance:

A. Oxygenic index%: >90

B. Level combustion: SO

C. Vertical combustion: SO

D. Water content rate: 10.9%

E. Capacity: 1.15g/cm3

F. Static bending intensity: 169.46Mpa

G. Density: T/ m3 1.13

H. Water resistance: Without chalking for 24 hours and there is no change on surface

I. No “Three-wastes” (waste water, waste gas and waste residue), no pollution and environmental protection 3.Mgo board specifications:

| thickness | 3-20mm |

length*width | 2440*1220mm 2400*900mm 3000*1200mm 2750*1200mm |

The product is formed with crushed crop straw or sawdust and some inorganic chemical materials at one time after roller-extruding. The source of raw materials is widely and they are purchased easily for customers.

1.Batching system The agitator mixes liquid and solid raw material. It feeds mixed slurry into forming system, providing slurry for forming system.

1.Batching system The agitator mixes liquid and solid raw material. It feeds mixed slurry into forming system, providing slurry for forming system.  2.Forming line and batching platform The forming line is the mainframe for the whole line. Mixed wet slurry is fed onto moulding board moving with constant speed, via a storage tank and feeder.

2.Forming line and batching platform The forming line is the mainframe for the whole line. Mixed wet slurry is fed onto moulding board moving with constant speed, via a storage tank and feeder.  3. Automatic board receiving system: The wet board will enter the automatic receiving system after has been cut with presetting length.This system adopted microcomputer and double elevators.The wet board with moldboard will enter the curing transporter layer by layer following the order of the microcomputer twenty boards with one curing transporter, and the double elevator achieve process production and volume-produce through alternate use.

3. Automatic board receiving system: The wet board will enter the automatic receiving system after has been cut with presetting length.This system adopted microcomputer and double elevators.The wet board with moldboard will enter the curing transporter layer by layer following the order of the microcomputer twenty boards with one curing transporter, and the double elevator achieve process production and volume-produce through alternate use.  4. Solidifying rom with trackway style: This set of production line is equipped with four trackway,each way can be placed multiple curing transporters and processed solidifying here. The multiple trackway system can meet the purpose of volume-produce.

4. Solidifying rom with trackway style: This set of production line is equipped with four trackway,each way can be placed multiple curing transporters and processed solidifying here. The multiple trackway system can meet the purpose of volume-produce.  5.Demoulding machine This demoulding machine separately absorbs MgO boards and mould board with a vacuum device. It puts MgO board and mould into respective stacking machine separately.

5.Demoulding machine This demoulding machine separately absorbs MgO boards and mould board with a vacuum device. It puts MgO board and mould into respective stacking machine separately.

Company Information

Company Information  Packaging & Shipping

Packaging & Shipping  Our Services

Our Services  1. Our company has professional installation & debug teams. We will install and test the production line at the customers' place until the equipment produces the qualified products. 2. We supply the accessories all the year round. The guarantee time of the equipment is one year. 3. We are responsible for the technical consultation and service all the year around and solve all kinds of technical problems at any time. 4. We can help the customer to do the consignment and the relevant procedure for import and export. 5.If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms.

1. Our company has professional installation & debug teams. We will install and test the production line at the customers' place until the equipment produces the qualified products. 2. We supply the accessories all the year round. The guarantee time of the equipment is one year. 3. We are responsible for the technical consultation and service all the year around and solve all kinds of technical problems at any time. 4. We can help the customer to do the consignment and the relevant procedure for import and export. 5.If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms.  Contact us if you need more details on Composite Partition. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Composite Partition、Composite Partition. If these products fail to match your need, please contact us and we would like to provide relevant information.

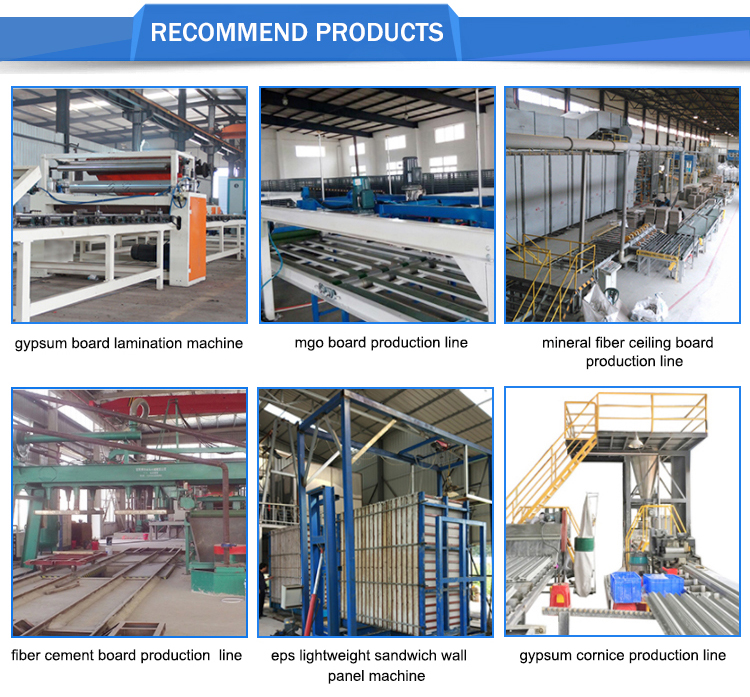

Contact us if you need more details on Composite Partition. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Composite Partition、Composite Partition. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : MgO board production line

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery