Economic Automatic New Design Wall Cladding MGO Board Production Line

Product Description

2.Applications: Internal and external walls, hotels, restaurants, factory shopping malls, cinemas, theatres, hospitals, train or bus terminals, airports, and school constructions. 3.Characteristics:

1. Light weight, impact resistant

2. Non-burning, moisture resistant

3. Sound proofing, heat insulating

4. Chemical resistant, insect-proof, erosion resistant

5. 100% no Asbestos contained. 4.MgO Fireproof Board Contrast With Traditional Fireproof Board:

| MGO BOARD | Traditional Fireproof Board |

Density(kg/m3) | 1.0*103 | (approx)1.*1.03 |

Mositure Absorption Rate(%) | 11 | About 2 times higher |

Anti- bending strength (kgf/cm3) | 224 | Worse mgo board |

Combustion- Resistance Class1 | Above 3mm | 6mm-12mm |

Flexibility | Good | Worse than mgo board |

Sound-Resistance | 44-45dB | (approx)45dB |

Content of harmful substances | 100% don't have | Have harmful substances |

Detailed Images 1.Batching system The agitator mixes liquid and solid raw material. It feeds mixed slurry into forming system, providing slurry for forming system.

Detailed Images 1.Batching system The agitator mixes liquid and solid raw material. It feeds mixed slurry into forming system, providing slurry for forming system.  2.Forming line and batching platform The forming line is the mainframe for the whole line. Mixed wet slurry is fed onto moulding board moving with constant speed, via a storage tank and feeder.

2.Forming line and batching platform The forming line is the mainframe for the whole line. Mixed wet slurry is fed onto moulding board moving with constant speed, via a storage tank and feeder.  3. Automatic board receiving system: The wet board will enter the automatic receiving system after has been cut with presetting length.This system adopted microcomputer and double elevators.The wet board with moldboard will enter the curing transporter layer by layer following the order of the microcomputer twenty boards with one curing transporter, and the double elevator achieve process production and volume-produce through alternate use.

3. Automatic board receiving system: The wet board will enter the automatic receiving system after has been cut with presetting length.This system adopted microcomputer and double elevators.The wet board with moldboard will enter the curing transporter layer by layer following the order of the microcomputer twenty boards with one curing transporter, and the double elevator achieve process production and volume-produce through alternate use.  4. Solidifying rom with trackway style: This set of production line is equipped with four trackway,each way can be placed multiple curing transporters and processed solidifying here. The multiple trackway system can meet the purpose of volume-produce.

4. Solidifying rom with trackway style: This set of production line is equipped with four trackway,each way can be placed multiple curing transporters and processed solidifying here. The multiple trackway system can meet the purpose of volume-produce.  5.Demoulding machine This demoulding machine separately absorbs MgO boards and mould board with a vacuum device. It puts MgO board and mould into respective stacking machine separately.

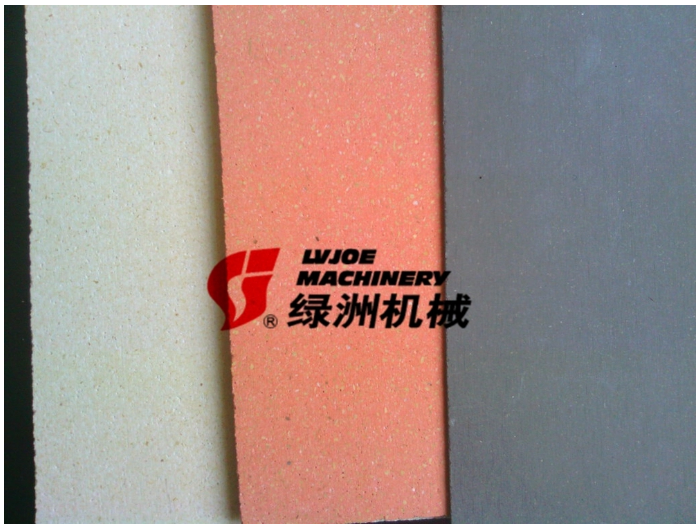

5.Demoulding machine This demoulding machine separately absorbs MgO boards and mould board with a vacuum device. It puts MgO board and mould into respective stacking machine separately.  HOT Finished Board

HOT Finished Board

Our Customers

Our Customers  Certifications

Certifications

Our Services 1. Best Price; we have our own factory, who has been specialized in full automatic pvc laminated gypsum ceiling tiles machine for more than 15 years, and you are welcome to our factory any time.

Our Services 1. Best Price; we have our own factory, who has been specialized in full automatic pvc laminated gypsum ceiling tiles machine for more than 15 years, and you are welcome to our factory any time.2. Superior Quality; quality is the life of all our business.

3. Best Service; we are the special International Trading Company of our factory, and especially focus on exporting business.

4. Best after-sale service; our engineers will design scale of whole production line and help you with installation and commissioning, and train your workers or employees until they know how to operate all equipment. Company Information

Best regards James Yang ADD: 17th, NanYan Road Economical and Technological Development Zone,Shijiazhuang City,Hebei,China Mobile Phone:+8615832254694 WeChat:15832254694 E-mail:lvjoe3ATgreensontech.com Contact us if you need more details on high capacity. We are ready to answer your questions on packaging, logistics, certification or any other aspects about high capacity、high capacity. If these products fail to match your need, please contact us and we would like to provide relevant information.

Best regards James Yang ADD: 17th, NanYan Road Economical and Technological Development Zone,Shijiazhuang City,Hebei,China Mobile Phone:+8615832254694 WeChat:15832254694 E-mail:lvjoe3ATgreensontech.com Contact us if you need more details on high capacity. We are ready to answer your questions on packaging, logistics, certification or any other aspects about high capacity、high capacity. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : MgO board production line