Mgo board production line with lamination

Product Description

Product Description Fireproof Materials/ Fireproof mgo board (usually called magnesium oxide board) is the building material widely used in the construction area.The stable magnesium colloid is reinforced by middle alkali glass fiber net and stuffed by light material then becomes new flameless decorative material.

Composition:The materials of paper magnesium fireproof board are Magnesia(Mgo), Magnesium Chlorid(MgCl2) and alkali glass fiber net.

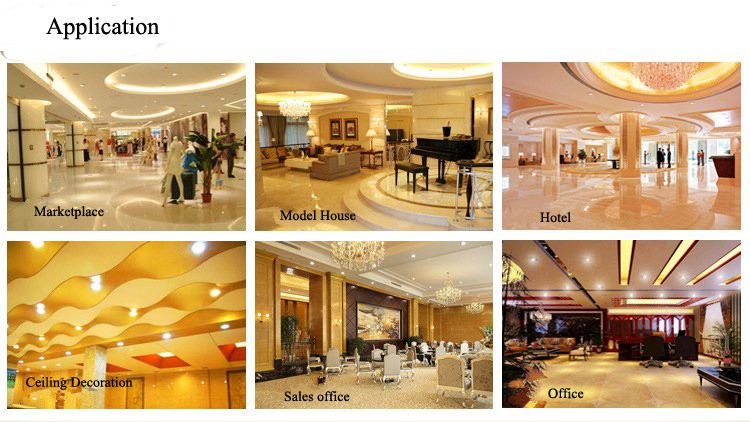

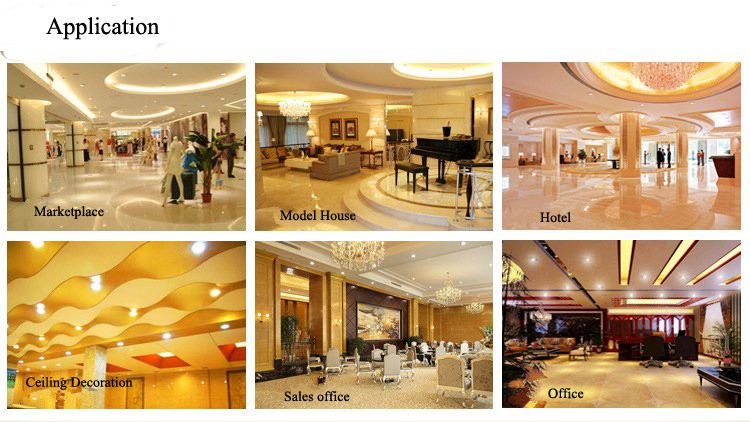

Applications: Internal and external walls, hotels, restaurants, factory shopping malls, cinemas, theatres, hospitals, train or bus terminals, airports, and school constructions. Characteristics:

1. Light weight, impact resistant

2. Non-burning, moisture resistant

3. Sound proofing, heat insulating

4. Chemical resistant, insect-proof, erosion resistant

5. 100% no Asbestos contained.

Features

1. More space efficient, easily drilled for plumbing

2. Can be cut and routed, can be decorated, painted or tiled

3. Easily installed by nails or screws

4. Can be flexed to fit curved surfaces

5. Scientific prescription,real green and environmental-friendly material.

Specifications

1. 2,440*1,220mm,2400*900m600*600mm

2. Thickness: 3 - 20mm

3. Different sizes are available.

4. 3000*1200mm,2750*1200mm,1,830*915mm

Mgo board production line adopts the automatic template device to save the labour cost. It also adopts automatic coating release agent system, by this way the release agent is evenly, less dosage and clean. Roller and forming roller precision is high that makes the board uniform thickness and smooth. Automatic cutting film system adopts fixed length cutting method, cutter does not hurt the template.

Mgo board production line adopts the automatic template device to save the labour cost. It also adopts automatic coating release agent system, by this way the release agent is evenly, less dosage and clean. Roller and forming roller precision is high that makes the board uniform thickness and smooth. Automatic cutting film system adopts fixed length cutting method, cutter does not hurt the template.

Detailed Images Automatic board feeding machine Batching platform

Batching platform

This kind of feeding platform is made of medium carbon steel plate and heavy caliber medium carbon steel tube. On the head position of the forming line, there is equipped multiple feed opening, which can meet the requirements of different specification of Mgo board. Above the platform, there is installed three sets of blenders, which are used to stir different kind of raw materials sufficiently. There is also equipped automatic releasing agent device,which is used to guarantee the sufficient painting on the moldboard surface. It is adopted slipping silo to feed material and achieving save labor and time.

There is equipped two sets of sucker on the head section of the production line,while there are moldboard elevators on both sides of the forming line. The double moldboard elevators and suckers guarantee the supplying of moldboard continuously and can meet volume-produce of Mgo board.

Forming line

Forming line

This kind of line combined stainless steel tube and convey belt style. The stainless steel tube have been processed and polished subtly on the surface, all of the tubes are maintaining on a same level, which achieved greatly reduce wet waste board rate and guarantee the smooth surface,flattening,well-distribute and smallest error of the board. This line is adopted our unique designing of automatic wet board cutter controlling system, which achieving the purpose of cutting the wet board line rapidly and won't hurt the moldboard according to the presetting length and microprocessor control and guarantee the precise length of the finished board.

Automatic board receiving system

Automatic board receiving system

Solidifying rom with trackway style

Solidifying rom with trackway style

Automatic mould move system

Automatic mould move system

The automatic mould move system that adopt the double cupulas and double lifters, stack the Moulds and the glass magnesium boards each other,there is a conveying track between the mould stacker and the forming line, it can carry out the quick conveying, so that the continuous producing. The glass magnesium boards will be conveying to the edge cutting saw and start the edge cutting for cutting for getting the dimension of the boards what we request.

Lamination

Lamination  Packing & Delivery

Packing & Delivery  Contact us if you need more details on mgo board Lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about laminating machine、MgO board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on mgo board Lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about laminating machine、MgO board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Composition:The materials of paper magnesium fireproof board are Magnesia(Mgo), Magnesium Chlorid(MgCl2) and alkali glass fiber net.

Applications: Internal and external walls, hotels, restaurants, factory shopping malls, cinemas, theatres, hospitals, train or bus terminals, airports, and school constructions. Characteristics:

1. Light weight, impact resistant

2. Non-burning, moisture resistant

3. Sound proofing, heat insulating

4. Chemical resistant, insect-proof, erosion resistant

5. 100% no Asbestos contained.

Features

1. More space efficient, easily drilled for plumbing

2. Can be cut and routed, can be decorated, painted or tiled

3. Easily installed by nails or screws

4. Can be flexed to fit curved surfaces

5. Scientific prescription,real green and environmental-friendly material.

Specifications

1. 2,440*1,220mm,2400*900m600*600mm

2. Thickness: 3 - 20mm

3. Different sizes are available.

4. 3000*1200mm,2750*1200mm,1,830*915mm

Mgo board production line adopts the automatic template device to save the labour cost. It also adopts automatic coating release agent system, by this way the release agent is evenly, less dosage and clean. Roller and forming roller precision is high that makes the board uniform thickness and smooth. Automatic cutting film system adopts fixed length cutting method, cutter does not hurt the template.

Mgo board production line adopts the automatic template device to save the labour cost. It also adopts automatic coating release agent system, by this way the release agent is evenly, less dosage and clean. Roller and forming roller precision is high that makes the board uniform thickness and smooth. Automatic cutting film system adopts fixed length cutting method, cutter does not hurt the template.Detailed Images Automatic board feeding machine

Batching platform

Batching platform This kind of feeding platform is made of medium carbon steel plate and heavy caliber medium carbon steel tube. On the head position of the forming line, there is equipped multiple feed opening, which can meet the requirements of different specification of Mgo board. Above the platform, there is installed three sets of blenders, which are used to stir different kind of raw materials sufficiently. There is also equipped automatic releasing agent device,which is used to guarantee the sufficient painting on the moldboard surface. It is adopted slipping silo to feed material and achieving save labor and time.

There is equipped two sets of sucker on the head section of the production line,while there are moldboard elevators on both sides of the forming line. The double moldboard elevators and suckers guarantee the supplying of moldboard continuously and can meet volume-produce of Mgo board.

Forming line

Forming line This kind of line combined stainless steel tube and convey belt style. The stainless steel tube have been processed and polished subtly on the surface, all of the tubes are maintaining on a same level, which achieved greatly reduce wet waste board rate and guarantee the smooth surface,flattening,well-distribute and smallest error of the board. This line is adopted our unique designing of automatic wet board cutter controlling system, which achieving the purpose of cutting the wet board line rapidly and won't hurt the moldboard according to the presetting length and microprocessor control and guarantee the precise length of the finished board.

Automatic board receiving system

Automatic board receiving system Solidifying rom with trackway style

Solidifying rom with trackway style Automatic mould move system

Automatic mould move system The automatic mould move system that adopt the double cupulas and double lifters, stack the Moulds and the glass magnesium boards each other,there is a conveying track between the mould stacker and the forming line, it can carry out the quick conveying, so that the continuous producing. The glass magnesium boards will be conveying to the edge cutting saw and start the edge cutting for cutting for getting the dimension of the boards what we request.

Lamination

Lamination  Packing & Delivery

Packing & Delivery  Contact us if you need more details on mgo board Lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about laminating machine、MgO board production line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on mgo board Lamination machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about laminating machine、MgO board production line. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : MgO board production line

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery