Hot sale profile bending machine manufacturer

Product Description

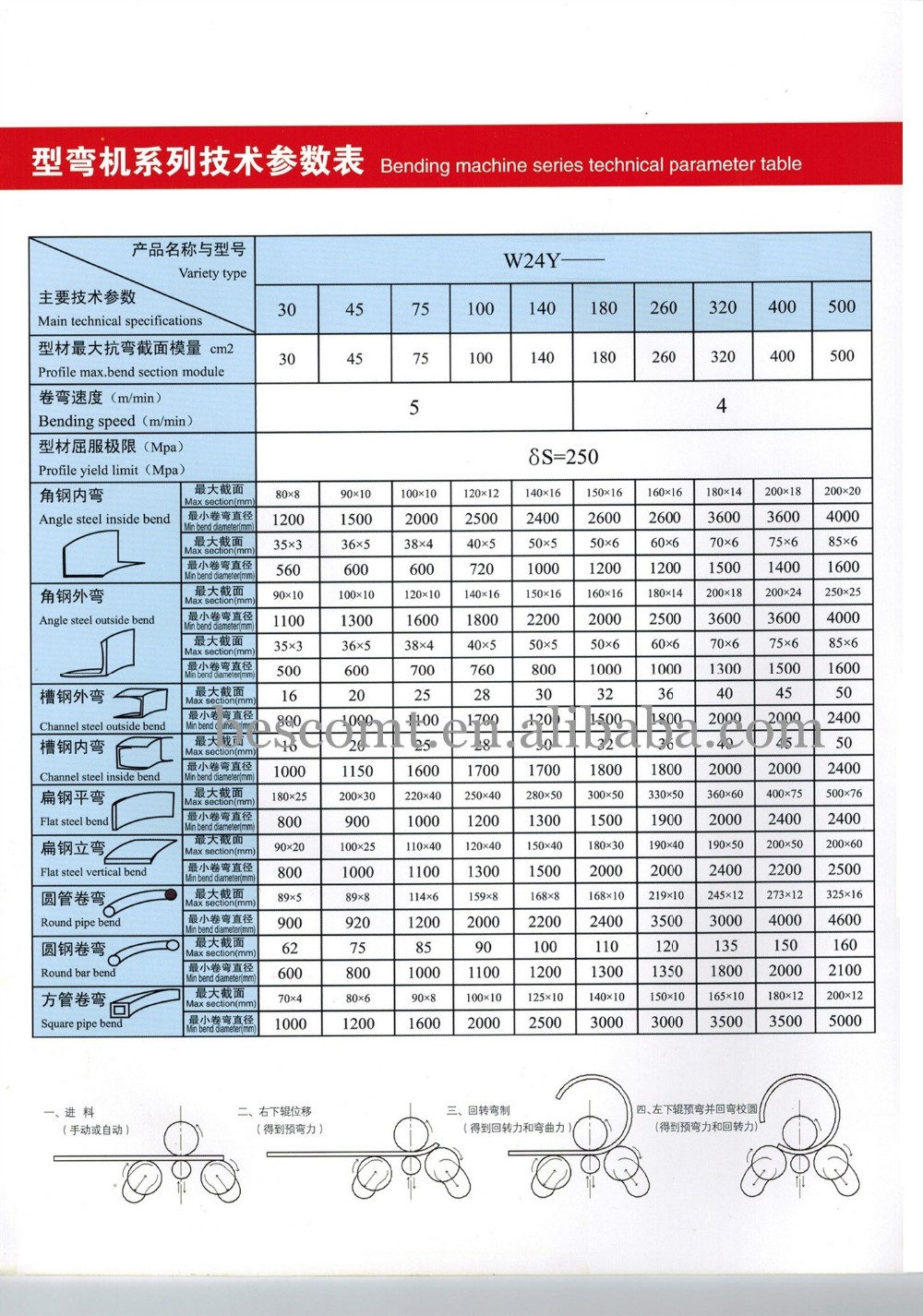

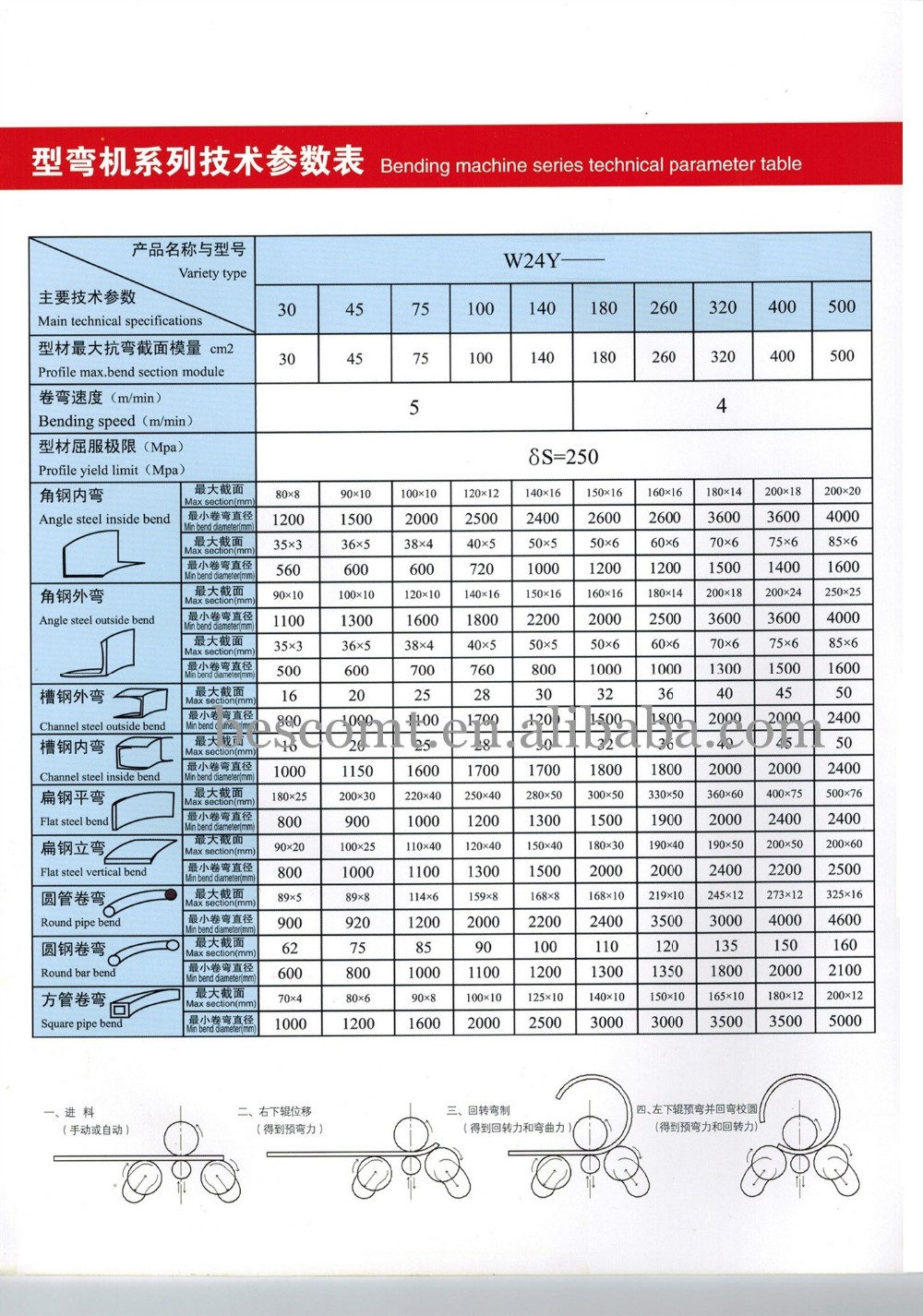

Product Description Product Application This Curve down Three-roller Bending Machine for Sectional Materials is a kind of universal equipment used to make the sectional materials into work pieces with different shapes such as Circle, arch and so on.

Main Features The machine is completely driven by the three-roller. It can achieve the pre-bent of the end in the sectional materials by adjusting the rollers and regulate the distortion of the c the asymmetric sectional materials generated in the bending process.

Main Features The machine is completely driven by the three-roller. It can achieve the pre-bent of the end in the sectional materials by adjusting the rollers and regulate the distortion of the c the asymmetric sectional materials generated in the bending process.

All of the above movements are controlled by the buttons in the push-button station.

Certifications

Sample

Sample

Detailed Images

Detailed Images  Roller 1, Top roller fixed,two bottom roller move byarc lifting around a fixed center.

Roller 1, Top roller fixed,two bottom roller move byarc lifting around a fixed center.

2,They can rising and falling separately alsocan rising and falling at the same time. 3,Side guid rollers to ensure the high qualityfor asymmetrical section bending.

4,Three drive rolls mounted with hydraulic

motor ,without slipping ,even for thinner ma-terial can be bent.

Hydraulic system .1,Full hydraulic transmission.

2,The machine adopts hydraulic pressing, sothe pressure is large and the performanceis stable.

3, Hydraulic guide rolls.

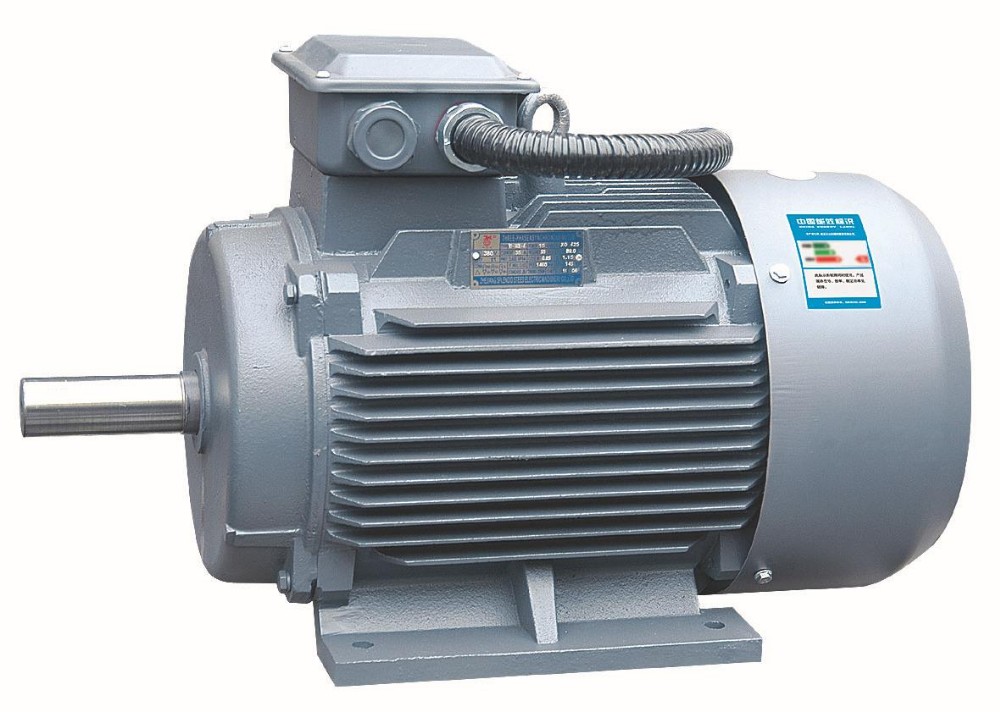

Main motor

Main motor

The main drive device includes main motor,reducer gear and etc

Control system

The operation table is set with indicators foreach parts movement.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * 24 hours online service * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * 24 hours online service * View our Factory. After-Sales Service

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Packing & Delivery

Our customers

Contact information

Contact information  Contact us if you need more details on profile bending machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about profile bending machine manufacturer、Hot sale profile bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on profile bending machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about profile bending machine manufacturer、Hot sale profile bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Main Features The machine is completely driven by the three-roller. It can achieve the pre-bent of the end in the sectional materials by adjusting the rollers and regulate the distortion of the c the asymmetric sectional materials generated in the bending process.

Main Features The machine is completely driven by the three-roller. It can achieve the pre-bent of the end in the sectional materials by adjusting the rollers and regulate the distortion of the c the asymmetric sectional materials generated in the bending process.All of the above movements are controlled by the buttons in the push-button station.

Certifications

Sample

Sample

Detailed Images

Detailed Images  Roller 1, Top roller fixed,two bottom roller move byarc lifting around a fixed center.

Roller 1, Top roller fixed,two bottom roller move byarc lifting around a fixed center.2,They can rising and falling separately alsocan rising and falling at the same time. 3,Side guid rollers to ensure the high qualityfor asymmetrical section bending.

4,Three drive rolls mounted with hydraulic

motor ,without slipping ,even for thinner ma-terial can be bent.

Hydraulic system .1,Full hydraulic transmission.

2,The machine adopts hydraulic pressing, sothe pressure is large and the performanceis stable.

3, Hydraulic guide rolls.

Main motor

Main motor The main drive device includes main motor,reducer gear and etc

Control system

The operation table is set with indicators foreach parts movement.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * 24 hours online service * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * 24 hours online service * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Packing & Delivery

Contact information

Contact information  Contact us if you need more details on profile bending machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about profile bending machine manufacturer、Hot sale profile bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on profile bending machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about profile bending machine manufacturer、Hot sale profile bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Roller benging machine > section bending machine

Premium Related Products

Other Products

Hot Products

Two Colors Plastic Injection Machine for PVC ProductsPlastic Multi-Color Injection Moulding Machines for PVCPlastic Injection Moulding Machine for Plastic FittingVertical Plastic Machinery Injection Mould Machine for PVCSingle Slider Injection Molding Mould Machine for Plastic FittingPVC Plastic Injection Molding Machine for Shoe SolePlastic Vertical PVC Injection Machine for Shoes SoleVertical Horizontal Plastic Injection Molding Machines for ShoesMulti-Color Plasticinjection Molding MachinesPVC Vertical Plastic Injection Moulding Machine for Hardware FittingVertical Rotary Table Injection Molding Machine for Hardware FittingPlastic PVC Injection Molding Machine for PlugInjection Molding Machine for AC Ad PlugVertical Plastic Injection Molding Machine for Plug ConnectsVertical PVC Injection Moulding Machine for Connect CableVertical Plastic Injection Moulding Machine for Injection Machinery